Self Leveling Compounds For Use With Hydronic Radiant Floors

The Geeks Guide to Self Leveling Compounds And Radiant Panels

Our radiant panels have a flatness requirement similar to most flooring products. “The requirement for flatness is defined as the maximum difference between two adjacent high points and the intermediate low point. The maximum acceptable difference in level is 3/16″ of an inch in a 10-ft. radius”.

Fixing areas that do not meet this standard is usually done with products called self-leveling compounds (SLCs). To the un-initiated, there are a bewildering number of them. There are 3 basic types of materials used, products for application in different thicknesses, and products with and without fiber for added strength.

How to Choose a Self-Leveling Compound

Types of Self-Leveling Compound

The important thing to remember is with so many available products, choosing the right compound is more complicated than you might think. There are many different products for different thicknesses to be leveled. For example, radiant panels generally require a product designed to be applied with small depressions feather-edged for smoothness. Other variables to consider are thickness, set times, smoothness, and flow rate. The reasons to use different compounds depends on your specific project conditions.

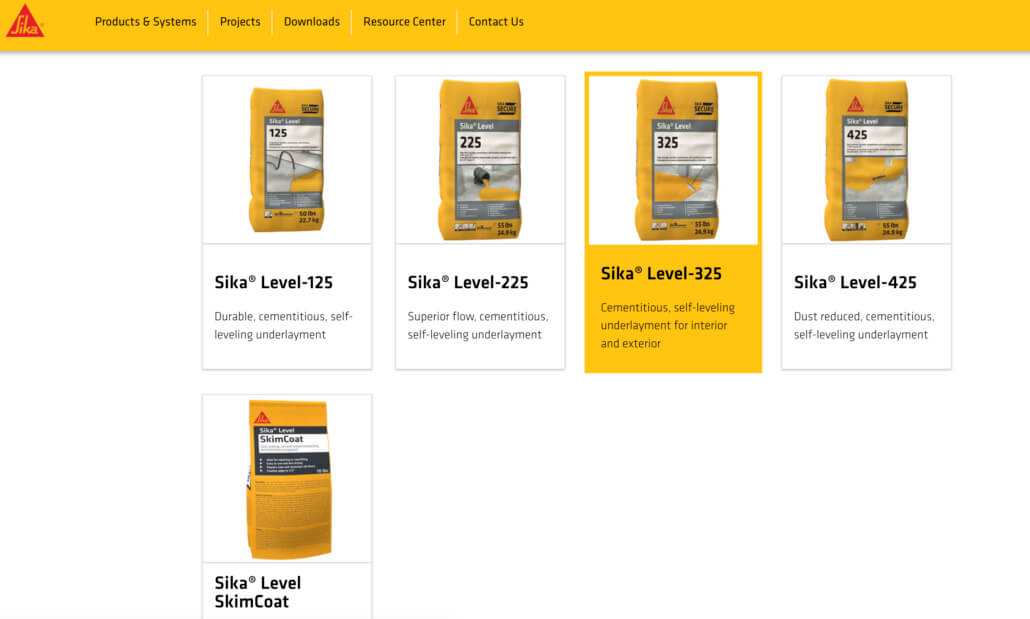

So before I go through the many types of self leveling compounds, I’m going to provide you with a chart of just one of the brands and just one of several types of self-leveling compounds then I will go through the different types.

Each of the compounds pictured above are custom designed for leveling a specific set time, thickness range etc. The Sika Level Skim Coat is specifically designed to go from a “feather edge” to 1/2″ thick as shown below.

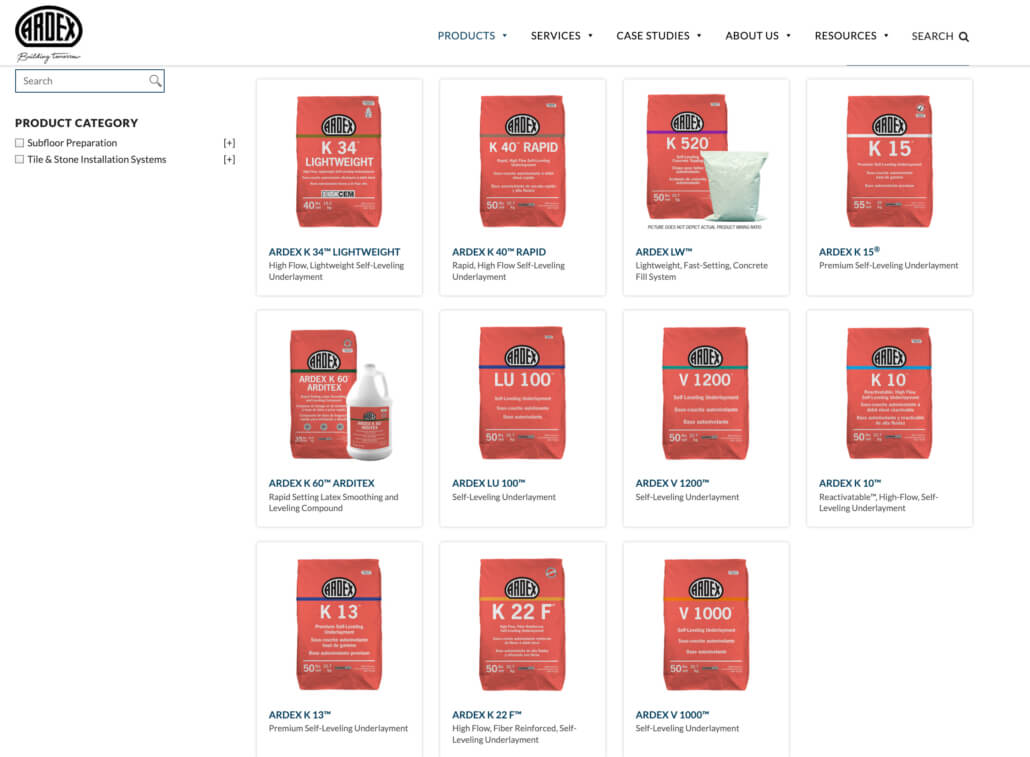

There are many brands of self-leveling compounds including Sika, Mapei, Sakrete, Henry, Ardex, Laticrete, LevelQuik and others. It will be extremely helpful to contact a qualified technical sales rep to help you select the best product for your project.

How to Smooth Out Floor Imperfections and Feather Edges

Many brands have products for thin-coating and feather-edging to fill depressions in floor areas.

Sika Level SkimCoat Self-Leveling Underlayment

Sika® Level SkimCoat is a one-component, easy to use and fast drying, cementitious skim mortar ideal for the repair or reprofiling of concrete, approved wood subfloors, and correctly prepared ceramic or quarry tiles before the installation of Sika® Level products or final floor coverings. It can be installed as a true featheredge as well as filling voids and leveling defects up to 1/2” (13 mm) in depth.

Mapei Ultraplan Easy – Self-Leveling Underlayment

Mapei Ultraplan Easy is a quick-setting, self-leveling underlayment that requires only a clean, soundly bonded, properly prepared and primed substrate before application.

Understanding 3 Basic Types of Floor Leveling Compounds

Quick Summary: Chemistry Driven Selection for Optimum Conditions

-

Gypsum (calcium sulfate): best for smoothness/flatness and low shrink in dry interior conditions; not ideal where moisture is questionable or high water temperatures required for radiant since plaster can degrade if water temperatures are too high.

-

Portland cement: Best general-purpose, broader moisture tolerance, widely compatible; manage shrink and moisture/pH.

-

CAC / alumina cement: Best for fast set / fast return-to-service and high early strength; must respect formulation limits to avoid long-term performance surprises.

Calcium Sulfate Cement Pros and Cons Detailed Breakdown

Calcium sulfate (gypsum / anhydrite)–based SLCs Primary binder: calcium sulfate hemihydrate (“plaster of Paris”, CaSO₄·½H₂O) or anhydrite (CaSO₄) Crystal-growth hardening: Strength comes from interlocking gypsum crystals rather than the C-S-H gel you get in cement.

Low shrink, very flat: Often excellent for large pours and smoothness.

Moisture sensitivity is real: Calcium sulfate matrices can soften or lose strength with sustained moisture exposure; they’re typically not the best choice where there’s ongoing moisture vapor emission or wet service.

Downsides: Plaster can be damaged by a high water temperatures if there is a control control failure. When gypsum-based materials contact Portland-cement materials, you can create ettringite-forming conditions at interfaces if moisture is present (not always catastrophic, but it’s why manufacturers are strict about primers, isolation layers, and moisture limits).

Portland Cement–based SLCs: Best Use Circumstances

Primary binder: Portland cement clinker phases + gypsum set regulator

Main hydration products:

-

C-S-H gel (calcium silicate hydrate) = the “glue” that gives strength

-

CH (calcium hydroxide, portlandite) = byproduct

-

Early controlled ettringite formation helps with set and dimensional behavior

What that means in practice:

-

Generally more water tolerant than gypsum systems (though still needs moisture testing and proper primers).

-

Shrinkage risk is higher than gypsum in many formulations (SLCs compensate with polymers, fillers, and shrink-reducing admixtures—but chemistry is still cement gel + water loss).

-

Good all-around substrate for many floor coverings/adhesives when installed within the manufacturer’s moisture/pH limits.

High-alumina Cement (CAC) Alumina Cement Based High-Strength / Fast-Set SLCs

Primary binder: calcium aluminate cement (often called CAC)

Two big chemistry features to understand

-

Very fast, very strong early set: CAC hydrates form quickly, so these mixes can be walkable/coverable fast and can reach high early strength.

-

“Conversion” phenomenon: Under warm/wet conditions, early CAC hydrates can convert to more stable phases with a different microstructure (often higher density but higher porosity), which can reduce long-term strength if the system wasn’t designed for it. Many modern products manage this with blended binders, additives, and tight formulation control.

What that means in practice

-

Great for rapid turnaround and high compressive strength (especially thin sections).

-

More sensitive to curing temperature/moisture history than Portland-cement SLCs—so following the product’s water ratio, thickness limits, and cure schedule matters a lot.

-

Very strong and fast setting, if used at correct temperature and water percentage.

Bottom Line Recommendation for Self-Leveling Cement

As I suggested before, get to know the technical sales rep for at least one of these brands and let them help pick the one that will work best for your situation and site conditions.