What Is Water Underfloor Heating? Everything You Need to Know

Water underfloor heating, also known as hydronic radiant floor heating, is one of the most energy-efficient and comfortable ways to heat a home. Unlike forced air or baseboard systems, it delivers consistent warmth from the floor up—eliminating drafts, cold spots, and noisy vents.

In this guide, we’ll explain how water underfloor heating works, how it compares to both electric radiant heating and forced air systems, and which construction methods work best. You’ll also find practical tips, system diagrams, and subtle product insights to help you plan a high-performance radiant system that lasts for decades.

What Is Water Underfloor Heating?

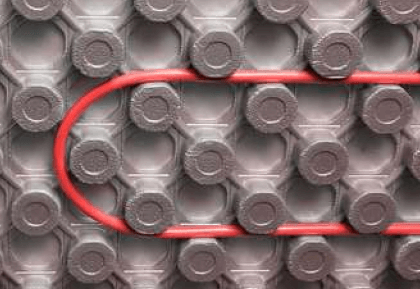

Water underfloor heating uses flexible tubing (usually PEX or PERT) installed beneath the floor surface. Warm water flows through the tubing, radiating heat upward and evenly warming the entire room.

Main Components:

- Tubing: Circulates warm water throughout each zone

- Manifold: Connects tubing loops and regulates flow

- Heat Source: Boiler, water heater, tankless water heater, or air-to-water heat pump

- Thermostat & Controls: Manage heat levels in each room

Benefits of Water Underfloor Heating

- Uniform heat from the floor up

- More energy-efficient than forced air

- No dust or allergens blown through vents

- No visible vents or radiators—more freedom in interior design

- Silent, zoned comfort

How It Compares to Electric Radiant and Forced Air Heating

Let’s break down the differences between the three most common residential heating systems:

| Feature | Water Underfloor (Hydronic) | Electric Radiant | Forced Air |

| Best For | Whole-home or large zone heating | Small areas (e.g., bathrooms) | Quick heat, cooling + heating combo |

| Install Cost | Higher upfront | Lower upfront | Moderate |

| Operating Cost | Low (if gas or heat pump used) | High (electricity) | Moderate to high (varies by fuel) |

| Comfort Level | Excellent (even radiant heat) | Very good in small areas | Uneven temps, airflow drafts |

| Noise | Silent | Silent | Noisy fans and ducts |

| Allergy-Friendly | Yes | Yes | No (circulates dust/pollen) |

| Zoning Capability | Excellent | Room-by-room | Limited (unless zoned HVAC) |

| Floor Compatibility | Wide range (tile, wood, LVP) | Best with tile, stone | N/A |

| Cooling Capability | No | No | Yes |

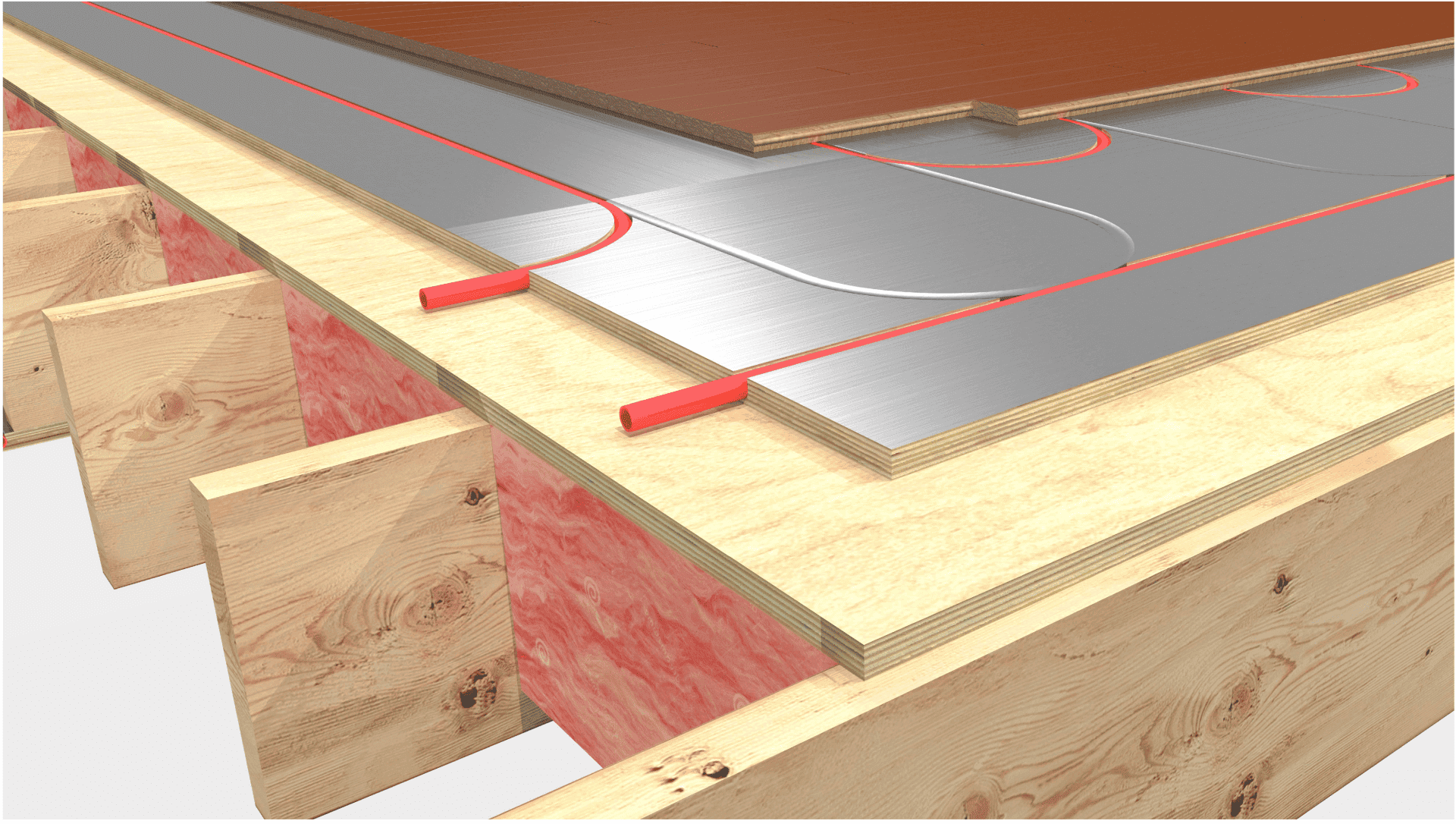

Ideal Construction Types for Water Underfloor Heating

1. Concrete Slabs (Basements, Garages, New Construction)

- Tubing embedded in 4″+ concrete

- Best when installed with insulation underneath

WBI Panel Options:

InsulHeat™ from WBI combines rigid EPS insulation and tubing channels, offering a durable, code-compliant solution for radiant heat in new slabs.

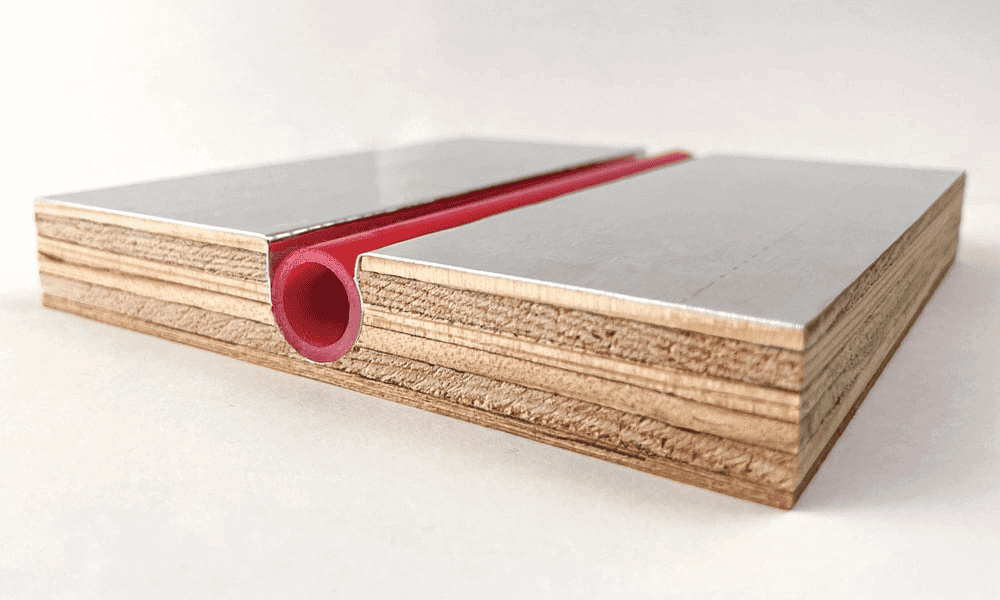

2. Wood Subfloors (Remodels or New Builds)

- Panels or tubing above subfloor with cement board or underlayment

- Ideal for second floors, kitchen remodels, or whole-home retrofits

WBI Panel Options:

- RadiantBoard™ (for direct install over wood subfloors)

- ThermalBoard™ (MDF-based, grooved panel with aluminum for fast heat transfer)

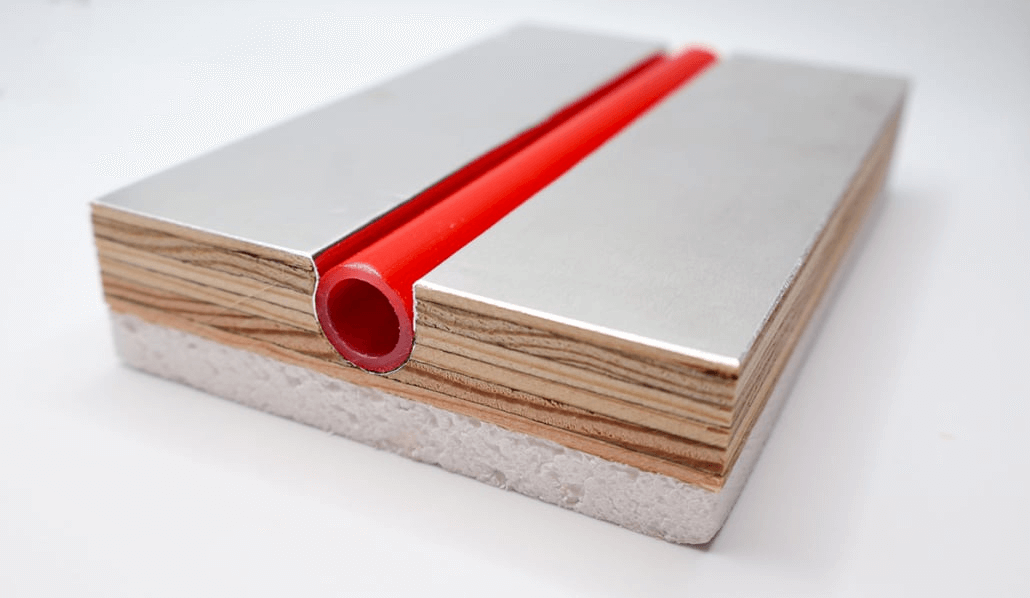

3. Retrofits or Over Concrete

- Use of EPS-backed panels for insulation and heating in one step

- Raises floor height slightly but improves energy efficiency

EPS Panel Options:

- RadiantBoard EPS™

- ThermalBoard EPS™

Designed for over-concrete installs where additional insulation is needed.

Compatible Flooring Types

Water underfloor systems are compatible with a wide range of flooring types, as long as you follow heat compatibility guidelines:

- Tile & Stone: Excellent heat conductors

- LVP / LVT: Check for radiant-approved products

- Engineered Wood: Best for stability under thermal cycling

- Carpet: Use low-R pads and tight weaves

- Solid Hardwood: Must be approved by the manufacturer

Installation Basics

How It Works:

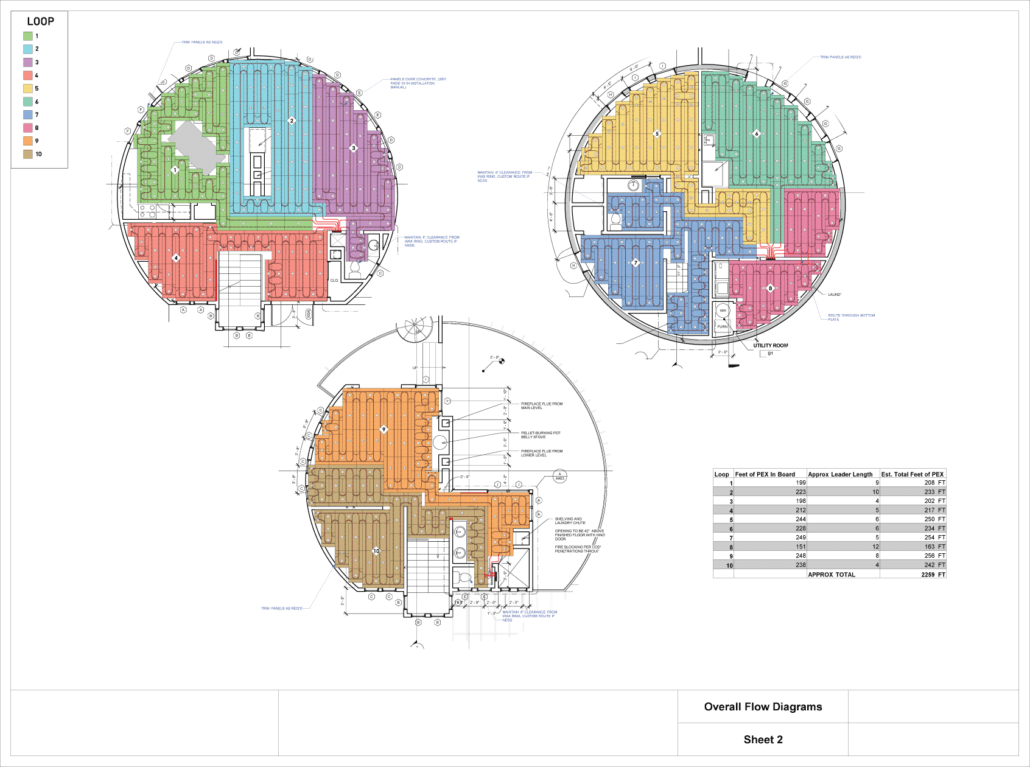

- Design Layout (loop spacing, zoning, heat load)

- Install Panels or Prep Slab

- Lay Tubing (200-250 ft max per loop)

- Connect to Manifold

- Pressure Test System

- Cover with Flooring or Pour Concrete

System Controls and Zoning

One of the key advantages of water underfloor heating is precise zone control. Each room or group of rooms can have its own thermostat, allowing for:

- Energy savings in unused rooms

- Personalized comfort settings

- Smart home integrations

Maintenance and Longevity

Water-based radiant systems are low maintenance if installed correctly. With high-quality tubing (like oxygen-barrier PEX) and a properly sized manifold and pump, you can expect:

- 30–50 years for tubing lifespan

- 15–25 years for manifolds, pumps, and thermostats

Tip: Annual inspections and system flushes (every 5–10 years) keep everything running smoothly.

Summary: When Water Underfloor Heating Is the Right Choice

Water underfloor heating offers unmatched comfort, energy efficiency, and design flexibility—especially when compared to forced air or electric radiant systems. If you’re building new, renovating, or upgrading a cold basement, hydronic radiant systems can provide decades of silent, consistent warmth.

WBI radiant panels—like InsulHeat™, ThermalBoard™, and RadiantBoard EPS™—are engineered for specific applications (subfloor, slab, retrofit), ensuring efficient and reliable heating in any room of the home.