Understanding Radiant Floor Heating Systems: A Complete Guide for Contractors and Homeowners

Radiant Floor Heating Systems: A Practical Guide for Homes and Projects

Radiant floor heating systems have become one of the fastest-growing comfort upgrades in residential construction. Contractors appreciate the efficiency, easy zoning, and stable heat delivery. Homeowners love the warm floors, quiet operation, and reduced energy bills. As energy codes tighten and heat pumps continue to grow in popularity, radiant systems offer a way to improve comfort while maintaining low water temperatures that enhance overall system performance.

If you are evaluating radiant floor heating systems for new construction, remodels, or additions, this guide breaks down everything you need to know: how they work, what components matter, common installation questions, and which applications benefit most. We will also touch on panel-based hydronic systems, including high-performance options like Radiantboard, Thermalboard, and EPS based insulation panels from Warm Brothers Inc. (WBI) that simplify installation and help optimize system efficiency.

What Is a Radiant Floor Heating System

A radiant floor heating system uses warm water circulating through PEX tubing or electric heating cables under the floor surface. Instead of heating air in a room, radiant systems warm the floor, which then warms the space through direct heat transfer and natural convection. The result is incredibly stable, even comfort without drafts or temperature swings.

There are two major types:

- Hydronic radiant floor heating uses a boiler or heat pump to heat water that circulates through PEX tubing.

- Electric radiant floor heating uses electric resistance mats or cables.

Hydronic systems are preferred for whole-home heating because of their lower operating cost, wide compatibility with modern heat pumps, and scalability. Electric mats are usually best for small spaces that need simple floor warming.

Why Radiant Floor Heating Systems Are Growing in Popularity

1. Superior comfort

Radiant floors eliminate cold spots by heating the largest surface in the room. Heat from the floor radiates to warm people and objects instead of heating air, eliminating hot air stratification at the ceiling.

2. Works extremely well with heat pumps

Today’s air-to-water and ground source heat pumps perform best at low water temperatures. A well-designed radiant floor heating system can operate at 85 to 110 degrees water, often much lower than traditional hydronic systems.

3. Energy efficient

Since the floor is a massive heat emitter, it allows the system to maintain comfort with lower supply water temperatures. Lower water temperatures reduce energy consumption and increase the coefficient of performance (COP) for heat pumps.

4. Quiet and invisible

There are no noisy blowers, no air drafts, no ductwork restrictions, and no visible heat registers to compete with interior design.

5. Ideal for open concept layouts

Radiant systems excel in large, open rooms where forced air struggles to distribute heat evenly.

How Hydronic Radiant Floor Heating Systems Work

The basic components include:

-

Heat Source

Could be a heat pump, boiler, or combi unit. For high efficiency, the system should run at the lowest possible water temperature while still meeting the building’s heat load.

-

Manifold

Acts as the distribution hub for each radiant zone. Balancing valves allow precise control of each loop.

-

PEX Tubing

Typically 3/8 or 1/2 inch tubing is installed in a pattern such as serpentine or counterflow.

-

Control System

Thermostats and optional smart controls that regulate water temperature, staging, and zone timing.

-

Radiant Panel or Thermal Mass

The floor assembly spreads heat evenly. This includes options like concrete slabs, gypsum overpour, or above-subfloor radiant panels.

Radiant Floor Heating System Installation Methods

1. Concrete Slab Installations

The tubing is installed directly into the slab. This offers high thermal mass, even heat distribution, and long life. It works well for basements, garages, and slab-on-grade homes. The downside is slower response time.

2. Gypsum or Overpour Systems

Tubing is installed on the subfloor and encapsulated in a self-leveling topping. This increases mass and provides good heat output, although the assembly adds height and weight.

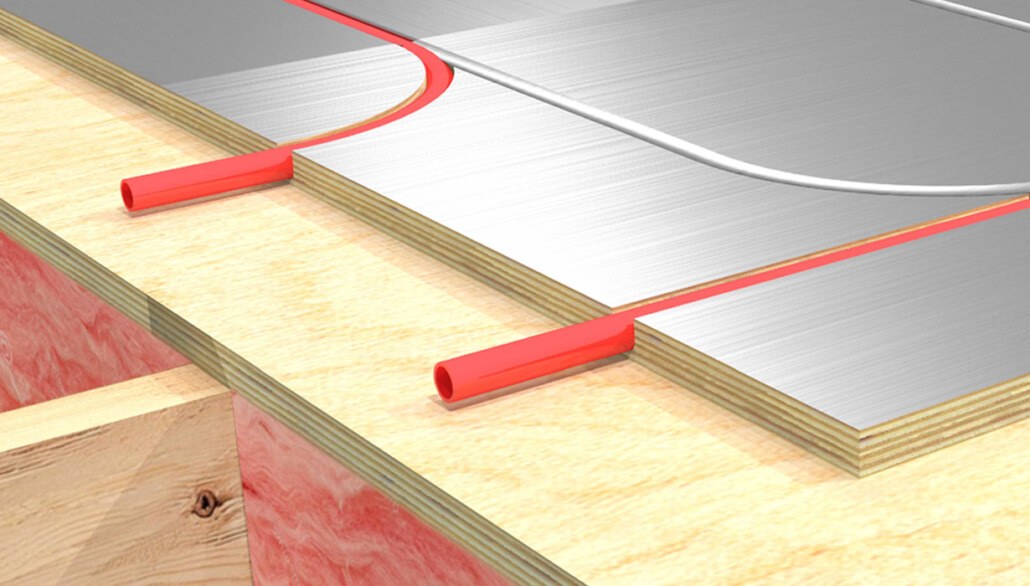

3. Above Floor Radiant Panels

This is where hydronic radiant systems have advanced the most in recent years. Panel systems provide high output, fast response, and efficient heat transfer without the height increase or weight load of overpours.

WBI’s Radiantboard, Thermalboard, Radiantboard EPS, and Thermalboard EPS are commonly used by contractors who want consistent performance and simplified installation. These panel systems use aluminum heat transfer layers bonded to MDF, plywood, or insulated EPS bases. They are designed to operate at lower water temperatures which benefits heat pumps and modern condensing boilers.

Why Panel Based Radiant Floor Systems Are Becoming the Contractor Standard

Contractors prefer panel systems because:

- They offer predictable performance across multiple flooring types

- They reduce installation time compared to staple up or gypsum

- They keep projects moving since there is no drying time

- They allow fast warm up and improved control

- They help meet stricter energy code requirements

Homeowners appreciate that panel systems give them warm floors without the long heat up times associated with poured systems. They also allow for quieter operation and more accurate room by room zoning.

Key Design Factors for Radiant Floor Heating Systems

1. Heat Loss Calculation

Every radiant system starts with a proper heat load calculation. A room with high glass area or poor insulation will need more output from the floor. This determines tube spacing, water temperature, and panel selection.

2. Floor Covering R Value

Thicker flooring acts as insulation and can reduce heat transfer. Tile or thin hardwood floors require lower water temperatures than carpet or thick engineered floors.

3. Tube Spacing

Tighter spacing (6 to 8 inches on center) results in more even surface temperatures and higher output. Wider spacing can be used in low load rooms but may require higher water temperature.

4. Subfloor and Insulation

The entire assembly matters. EPS insulated panels such as Radiantboard EPS or Thermalboard EPS from WBI help reduce downward heat loss and increase overall radiant efficiency.

5. Response Time

Panel systems have the fastest response time, concrete slabs the slowest. Fast response improves comfort and energy savings.

Ideal Applications for Radiant Floor Heating Systems

- New custom homes

- Basement remodels

- Whole home hydronic systems paired with heat pumps

- Main floor living spaces with large open areas

- High end remodels where comfort is a priority

- Homes with cold tile floors

- Garages, workshops, and accessory buildings

- Additions where extending ductwork is difficult

Where WBI Products Fit Naturally

WBI panel solutions complement radiant floor heating systems in several ways:

- Radiantboard is ideal for subfloor installations where consistent performance and fast warm up is needed.

- Thermalboard offers a cost friendly solution with strong heat output for common floor coverings.

- Radiantboard EPS and Thermalboard EPS add integrated insulation to reduce heat loss and optimize low temperature hydronic systems, especially when paired with heat pumps.

- Contractors value that these panels are simple to install, easily cut on site, and come in straight and combo boards for layout flexibility.

WBI products typically make up about 10 percent of a radiant system project cost yet directly influence comfort, control, and efficiency.

Conclusion

Radiant floor heating systems deliver comfort, efficiency, and reliability that forced air systems cannot match. For homeowners, they provide warm, quiet, draft-free living. For contractors, they offer a reliable and profitable heating method that pairs perfectly with the growth of heat pump technology.

Whether the project involves a slab on grade foundation, a remodel, an addition, or a full new home design, radiant systems offer a proven and future ready solution. Using high performance radiant panels like those from WBI helps maximize system output while keeping installation simple and predictable.

If you are evaluating a radiant floor heating system, consider the goals: lowest water temperature, best comfort, and a design that works with modern construction methods. With the right panel system and proper design approach, radiant heating becomes one of the most satisfying upgrades for both the contractor and the homeowner.