PEX Radiant Floor Heating: The Pros and Cons of PEX Radiant Floor Heating Systems

PEX Radiant Floor Heating Systems: Advantages and Disadvantages Explained

Radiant floor heating is one of the most comfortable and efficient ways to heat a home. At the heart of most modern radiant systems is PEX tubing, a durable and flexible plastic pipe that carries warm water beneath the floor surface. Together with high-performance heat transfer panels, PEX creates a system that delivers steady, quiet, and energy-saving comfort in any room of the home.

Let’s take a closer look at how PEX radiant floor heating works, why it’s so popular, and what homeowners should know before choosing this type of system.

How PEX Radiant Floor Heating Works

PEX (cross-linked polyethylene) tubing is designed to handle the high temperatures and pressures of hydronic heating systems. In a radiant floor installation, the tubing is laid out in evenly spaced loops beneath the floor. Warm water from a boiler or heat source circulates through the tubing, transferring heat upward through the floor surface.

The floor becomes a large, low-temperature radiator that gently warms the entire space from the ground up. There are no vents, fans, or noisy blowers. The result is even heat distribution, consistent comfort, and clean indoor air.

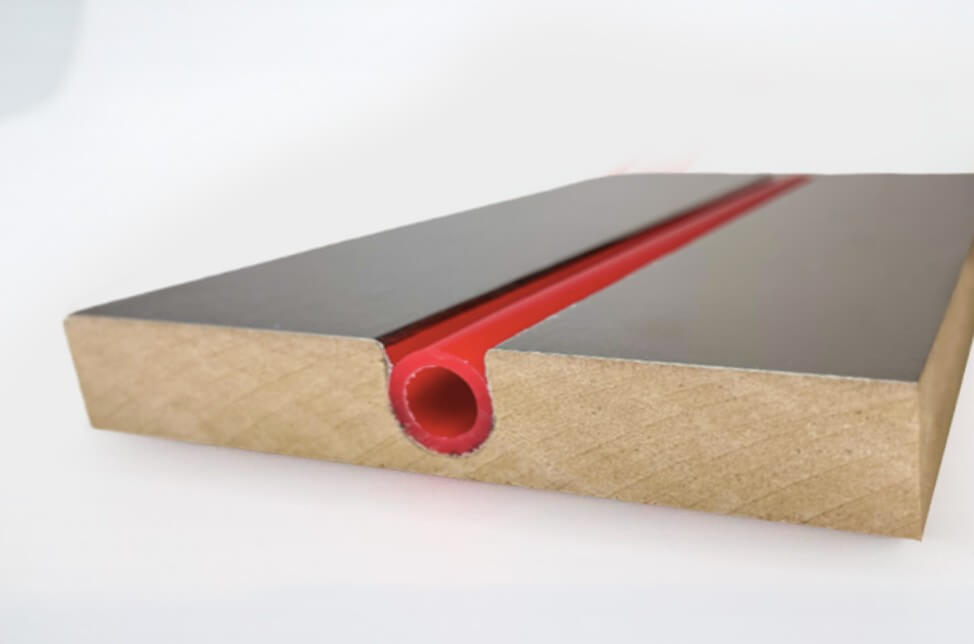

When paired with WBI radiant panels, PEX tubing fits into pre-routed channels that maximize heat transfer. The continuous aluminum surface of panels such as RadiantBoard or ThermalBoard spreads warmth evenly across the floor, allowing the system to run at lower water temperatures and reducing energy use.

The Advantages of PEX Radiant Floor Heating

1. Superior Comfort

Radiant heat feels natural because it warms the surfaces and people in the room, not just the air. There are no cold spots near floors or overheated air near ceilings. The result is balanced comfort throughout the space, even in rooms with high ceilings or large windows.

2. Energy Efficiency

Because radiant systems use lower water temperatures than baseboard or forced-air systems, they operate more efficiently. PEX tubing paired with high-efficiency boilers or heat pumps can reduce energy use by 15 to 30 percent compared to traditional systems.

WBI panels enhance that efficiency by improving the contact between the tubing and the floor surface, ensuring more of the heat from the water ends up warming the room instead of being lost to the subfloor.

3. Quiet, Clean Operation

Without air ducts or fans, radiant systems are completely silent. They also avoid circulating dust, allergens, and odors, making them ideal for households with allergies or respiratory sensitivities.

4. Flexible Design

PEX tubing is extremely flexible, which makes it easy to route around corners, obstacles, and tight spaces. It can be installed under a variety of floor types, including wood, tile, vinyl, and laminate, and works well in both new construction and retrofit projects.

5. Low Maintenance

Once installed, PEX radiant systems require very little maintenance. The tubing is highly resistant to corrosion and scale buildup. Quality installations can last 40 to 50 years with minimal upkeep.

6. Compatibility with Multiple Heat Sources

PEX radiant systems can be powered by gas, propane, electric, or even renewable heat sources like geothermal or solar thermal systems. This makes them adaptable to nearly any home design or energy preference.

Potential Considerations (and Why They’re Manageable)

Like any system, PEX radiant heating requires good design and proper materials to perform well. A few points to keep in mind:

- Installation quality matters. The layout of tubing and spacing affects performance and response time. Using professional design services ensures consistent results.

- Floor coverings affect output. Hard surfaces like tile transfer heat efficiently, while carpet or thick underlayment reduce it slightly.

- Upfront cost can be higher. Radiant systems cost more to install than baseboard or forced-air systems, but energy savings and comfort typically offset this over time.

With WBI’s radiant panels, many of these concerns are minimized. The panels provide consistent tubing channels, improve heat spread, and simplify installation. They can also be paired with EPS insulation layers for additional efficiency and sound control.

Why PEX and WBI Panels Are the Perfect Pair

PEX tubing performs best when it has excellent contact with a conductive surface. That’s where WBI RadiantBoard, ThermalBoard, and RadiantBoard EPS come in. These panels combine aluminum heat-transfer surfaces with precise PEX grooves to ensure even heat delivery.

The aluminum top layer spreads heat laterally, reducing temperature swings and allowing the boiler to run at lower temperatures. In turn, this lowers fuel or electricity use while keeping floor temperatures consistent and comfortable.

EPS-backed options like RadiantBoard EPS or ThermalBoard EPS provide built-in insulation, ideal for concrete or uninsulated subfloors. The result is a radiant system that is efficient, predictable, and long-lasting.

Best Applications for PEX Radiant Floor Heating

- Whole-home heating systems

- Basement or slab-on-grade installations

- Bathrooms and kitchens for added comfort

- Remodels or additions where quiet, efficient heat is desired

- Custom homes seeking energy efficiency and luxury comfort

Conclusion

PEX radiant floor heating combines proven technology, long-term reliability, and superior comfort. With the right design and materials, it provides steady warmth and lower energy costs for decades. When installed with WBI radiant panels, the system reaches its highest level of efficiency and performance.

Homeowners gain not only a more comfortable living space but also a smarter, cleaner, and more sustainable way to heat their home.