Hydronic Radiant Floor Heating: The Ultimate Guide for Efficiency and Comfort

Hydronic Radiant Floor Heating Guide for Efficient Home Comfort

Hydronic radiant floor heating has become one of the most desirable heating methods for modern homes. With energy efficiency becoming more important and heat pumps gaining popularity, hydronic radiant systems offer unmatched comfort and performance compared to forced air or electric resistance heating. For contractors, these systems create reliable, predictable heating solutions. For homeowners, they provide warm floors, quiet operation, and lower monthly bills.

Whether you are building a new home, upgrading an existing HVAC system, or designing a high efficiency custom project, understanding how hydronic radiant floor heating works is essential. This guide covers the fundamentals, common installation methods, design considerations, and how panel based radiant solutions like WBI’s Radiantboard and Thermalboard systems help maximize efficiency.

What Is Hydronic Radiant Floor Heating

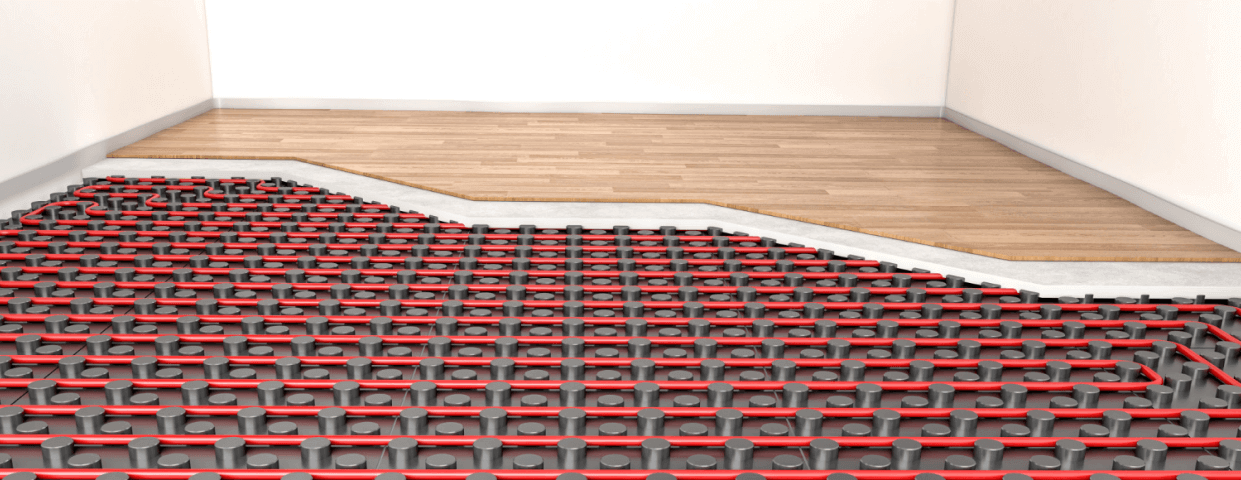

Hydronic radiant floor heating uses warm water circulated through PEX tubing beneath the floor surface to heat indoor spaces. The floor becomes a large radiant panel that warms the room through direct radiant transfer and natural convection. Instead of heating air and blowing it into rooms, the system heats the floor itself.

This creates one of the most comfortable and energy efficient heating experiences available today.

Key Features

- Low water temperature operation

- Consistent, even heat distribution

- Quiet, hidden, dust free heating

- Ideal pairing with air to water heat pumps and high efficiency boilers

How Hydronic Radiant Floor Heating Works

A typical hydronic radiant system includes:

1. Heat Source

This is usually:

- An air to water heat pump

- A high efficiency natural gas or propane boiler

- A combi boiler for domestic hot water and heating

- Less commonly, a pellet boiler or geothermal system

The heat source warms water to the temperature required by the radiant system, usually between 85 and 120 degrees depending on floor assembly.

2. PEX Tubing

Flexible PEX tubing is installed in loops through the floor. Common loop sizes are 3/8 inch and 1/2 inch.

3. Manifold

The manifold distributes water to the loops, manages balancing, and helps with zoning.

4. Controls

Thermostats, mixing valves, and circulators ensure the system maintains the correct water temperature and flow rates.

5. Floor Assembly

The structure that transfers the heat into the room. This can be a slab, gypcrete overpour, or above floor radiant panel.

Why Hydronic Radiant Floor Heating Is So Efficient

Hydronic radiant systems outperform traditional heating methods for several reasons.

1. Low Water Temperatures Reduce Energy Use

Hydronic radiant floors typically run at 85 to 110 degree water, far lower than the 130 to 160 degree water temperatures required by baseboard or forced air systems. This reduces energy consumption and allows heat pumps to operate at their highest possible COP.

2. Even Heat Distribution Boosts Comfort

Radiant floors warm the entire room uniformly. There are no drafts, no cold corners, and no temperature swings. The warm floor keeps occupants comfortable even with lower air temperatures.

3. Heat Pumps Pair Naturally with Radiant Systems

Air to water heat pumps are one of the fastest growing heating choices for cold climates. Hydronic radiant floors allow these systems to shine by enabling efficient low temperature operation throughout the winter.

4. Quiet, Clean Heating

There are no fans, ducts, or blowers. This eliminates noise and removes dust circulation, improving indoor air quality.

5. Zoning Efficiency

Hydronic radiant systems allow room by room zoning. This limits wasted energy and gives homeowners precise control over comfort.

Common Installation Methods

Hydronic radiant systems can be installed in several ways depending on the project.

1. Concrete Slab Radiant Heating

PEX tubing is embedded directly into a concrete slab.

Pros:

- Excellent thermal mass

- Even distribution

- Great for basements, garages, and slab homes

Cons:

- Slow warm up

- Hard to modify after installation

- Requires proper insulation beneath

2. Lightweight Concrete or Gypsum Overpour

Tubing is installed on the subfloor and covered with a topping layer.

Pros:

- Smooth, uniform heat output

- Ideal for tile and stone flooring

Cons:

- Added height

- Extra weight

- Long cure time that slows down construction

3. Above Floor Radiant Panel Systems

One of the fastest growing hydronic installation methods. Above floor radiant panels combine preformed tubing grooves with aluminum heat transfer layers that rapidly move heat into the room.

WBI’s radiant panel systems include Radiantboard, Thermalboard, Radiantboard EPS, and Thermalboard EPS, offering high performance, low water temperature operation, and simplified installation.

Pros:

- Fast installation with no cure time

- High efficiency heat transfer

- Fast warm up compared to slab systems

- Compatible with hardwood, LVP, tile, and carpet with proper underlayment

- Lightweight and ideal for remodels

Cons:

- Requires layout planning

- Small cost premium over staple up

4. Staple Up Underfloor Radiant Heating

PEX tubing is attached under the subfloor.

Pros:

- Good option for retrofits without removing flooring

- No changes to floor height

Cons:

- Lower efficiency than panel systems

- Requires aluminum plates for acceptable performance

- Needs strong insulation below

Design Considerations for Hydronic Radiant Heating

A high performing hydronic system depends on good design, not just good equipment.

1. Heat Load Calculation

Determines the required heat output for each space.

2. Tube Spacing

Tighter spacing increases heat output and improves floor temperature consistency.

3. Floor Covering Type

Floor coverings have different R values. Tile and thin hardwood work best. Carpet and thick engineered wood require higher water temperatures.

4. Insulation Below the Floor

Ensures heat moves into the living space rather than downward. EPS integrated radiant panels from WBI solve this challenge.

5. Water Temperature Planning

Designers aim for the lowest possible water temperature while meeting heat loads.

Where Hydronic Radiant Heating Works Best

Hydronic radiant floor heating is suitable for:

- New custom homes

- High performance homes and net zero projects

- Basements and slab homes

- Large open living areas

- Kitchens and bathrooms

- Additions and ADUs

- Heat pump based systems

- Homes in cold climates

- Upscale remodels

How WBI Radiant Panels Enhance Hydronic Radiant Floor Heating

WBI products play an important role in helping hydronic systems achieve high efficiency and excellent comfort.

WBI Radiantboard and Thermalboard systems provide:

- High output at low water temperatures

- Integrated aluminum for exceptional heat transfer

- Faster response times

- Predictable performance across all floor coverings

- Optional EPS backing for insulation and reduced heat loss

- Simplified installation using straight and combo panels

These performance benefits are especially valuable in heat pump driven systems or cold climate homes where efficiency matters.

Benefits for Contractors

Contractors often choose WBI radiant panels for hydronic projects because they offer:

- Faster installation compared to overpours

- Clean handling and easy site storage

- Lower labor costs

- Reliable, repeatable performance

- Simple cutting with standard tools

- Strong manufacturer support and layout design services

Benefits for Homeowners

Homeowners value hydronic radiant heating because it provides:

- Warm, comfortable floors

- Quiet, maintenance friendly operation

- Lower heating bills

- Better indoor air quality

- Compatibility with modern heat pumps

- Long lasting performance

Conclusion

Hydronic radiant floor heating is one of the most efficient, comfortable, and future ready heating solutions available today. Its ability to operate at low water temperatures, deliver even heat, and pair seamlessly with heat pumps makes it ideal for both new construction and high end remodels.

WBI’s Radiantboard, Thermalboard, and EPS backed panels help contractors and homeowners achieve maximum performance by improving heat transfer, reducing downward heat loss, and simplifying installation. When designed well, a hydronic radiant heating system provides comfort that no forced air system can match.