Hydronic Radiant Floor Heating Systems: The Complete Guide for Homeowners and Contractors

Hydronic Radiant Floor Heating: A Complete Guide for Homes & Contractors

Hydronic radiant floor heating systems have become one of the most efficient and comfortable ways to heat a home. Whether you are a builder, mechanical contractor, or homeowner planning a remodel, understanding how hydronic systems work and why they outperform traditional heating methods is essential. As energy codes become stricter and heat pumps grow in popularity, radiant floor heating offers a reliable way to deliver high comfort at low operating temperatures.

This guide covers the fundamentals of hydronic radiant systems, design principles, installation methods, ideal applications, and how high performance radiant panels like WBI’s Radiantboard and Thermalboard product lines help optimize system efficiency.

What Are Hydronic Radiant Floor Heating Systems

A hydronic radiant floor heating system uses warm water circulating through PEX tubing to heat the floor surface, which then warms the room through radiant energy and natural convection. Instead of blowing hot air through ducts, radiant floors create an even, comfortable temperature profile from the ground up.

Hydronic systems are preferred over electric radiant systems for whole home heating because they are more efficient, easier to pair with modern heat pumps, and capable of heating large areas at low operating cost.

How Hydronic Radiant Floor Heating Works

Every hydronic radiant system includes:

1. A Heat Source

Common options include air to water heat pumps, high efficiency boilers, and combi units. These systems heat the water that flows through the tubing.

2. PEX Tubing

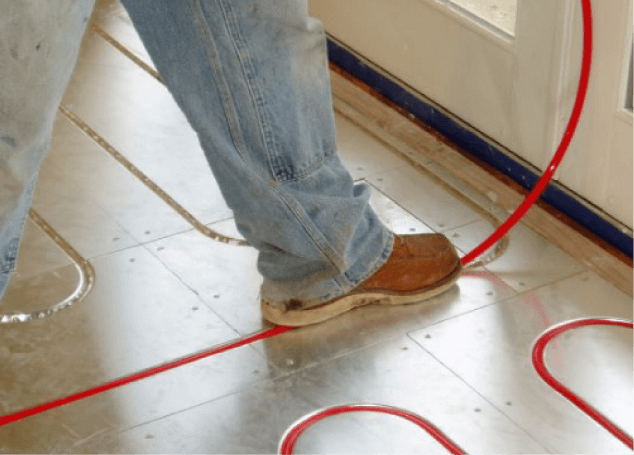

The tubing is installed in loops under or within the floor and carries warm water throughout each zone. Typical sizes include 3/8 inch or 1/2 inch PEX.

3. A Manifold

This distribution hub directs warm water into each loop and returns it to the heat source. Manifolds allow zoning, balancing, flow control, and temperature regulation.

4. Controls and Thermostats

Smart thermostats and hydronic controls regulate the water temperature and room temperature, ensuring efficient and comfortable operation.

5. A Radiant Floor Assembly

This could be a concrete slab, gypsum overpour, or above-floor radiant panel system. The assembly transfers heat from the tubing into the floor surface.

Why Hydronic Radiant Floor Heating Systems Are Growing Quickly

Superior Comfort

Warm floors eliminate drafts and cold spots. Even in the coldest climates, radiant heat creates consistent comfort throughout the room.

Energy Efficiency

Hydronic systems run at very low water temperatures, especially when paired with modern radiant panels. Lower water temperatures reduce energy consumption and improve heat pump performance.

Silent and Hidden Heating

No fans, blowers, or registers. Everything is concealed under the floor for a clean, quiet indoor environment.

Perfect for Heat Pumps

Air to water heat pumps have become a leading choice in energy efficient homes. Hydronic radiant floors are the ideal match because they operate efficiently at the same low water temperatures heat pumps produce.

Better Indoor Air Quality

No air movement means less dust, fewer allergens, and a cleaner overall environment.

Installation Methods for Hydronic Radiant Floor Heating

There are four main installation types, each with different strengths depending on the project.

1. Concrete Slab Installation

PEX tubing is placed on insulation and embedded in a poured concrete slab.

Benefits:

- Very even heat distribution

- Excellent for basements and slab on grade homes

- Durable and long lasting

Limitations:

- Slow response time

- Height and mass cannot be adjusted after installation

2. Gypsum or Lightweight Concrete Overpour

Tubing is installed on the subfloor and encapsulated in a gypsum based overpour.

Benefits:

- Smooth, uniform thermal mass

- Works well with tile and stone

Limitations:

- Added height

- Longer drying time

- Heavy and requires structural consideration

3. Above Floor Radiant Panels

This method has grown rapidly because it is fast, light, predictable, and compatible with modern low temperature heating equipment.

Panel systems like WBI’s Radiantboard, Thermalboard, Radiantboard EPS, and Thermalboard EPS simplify layout and maximize heat transfer by embedding aluminum paths directly above the tubing. This improves responsiveness and lowers required water temperatures.

Benefits:

- Easy to install with standard carpentry tools

- Fast warm up

- Works with hardwood, LVP, tile, carpet with proper underlay

- Reduced weight compared to overpours

- No lengthy drying period

4. Staple Up (Underfloor Installation)

PEX tubing is stapled underneath the subfloor with or without aluminum heat transfer plates.

Benefits:

- Useful for retrofits

- No change to floor height

Limitations:

- Lower efficiency without plates

- Harder to achieve even surface temperatures

- Requires strong insulation below

Key Design Considerations for Hydronic Radiant Systems

Heat Load Calculation

A precise heat loss calculation determines how much heat each zone needs. This drives tube spacing, water temperature, and panel selection.

Tube Spacing

Tighter spacing increases heat output and floor temperature consistency. Common spacing ranges from 6 to 12 inches depending on load.

Floor Covering R Value

Tile and thin hardwood perform best. Thicker engineered wood or carpet require adjusted water temperatures.

Subfloor Insulation

EPS underlayment or insulated radiant panels like WBI’s EPS options significantly reduce downward heat loss.

Water Temperature

Lower is better. Most radiant systems operate between 85 and 120 degrees depending on the assembly.

Manifold Placement

Shorter loops and balanced zones improve system stability and reduce pump energy.

Where Hydronic Radiant Floor Heating Works Best

- New custom homes

- Basements

- Main level living areas

- Kitchens and bathrooms

- Large open floor plans

- Additions where ductwork is difficult

- Garage and workshop floors

- Heat pump driven homes seeking high efficiency

Why WBI Radiant Panels Improve Hydronic System Performance

WBI panel systems play an important role in hydronic radiant design because they maximize heat transfer and improve low temperature efficiency.

WBI panels provide:

- Consistent heat output across the floor

- Faster response times than slab based systems

- Integrated aluminum for superior heat transfer

- EPS backed insulation options for reduced heat loss

- Simple layout using straight and combo boards

- The ability to run at lower water temperatures which is ideal for heat pumps

Using WBI panels allows many systems to operate at significantly lower supply water temperatures compared to staple up or overpour methods.

Advantages for Contractors

Contractors prefer panel based hydronic systems because they are:

- Fast to install

- Predictable in output

- Easy to design with preformed tube patterns

- Suitable for a wide range of floor coverings

- Supportive of scheduling because there is no cure time

- Less dependent on perfect jobsite conditions

WBI’s panels also ship well, store cleanly, and install with standard carpentry tools, which keeps the learning curve low for new installers.

Advantages for Homeowners

Homeowners choose hydronic radiant floor heating for:

- Warm floors in every room

- High energy efficiency

- No noise

- Better interior air quality

- Compatibility with renewable energy

- Long term comfort

For energy conscious customers, radiant systems combined with a heat pump offer one of the lowest operating costs available in residential heating.

Conclusion

Hydronic radiant floor heating systems provide unmatched comfort, efficiency, and design flexibility for both new builds and major renovations. When combined with modern heat pumps and high performance radiant panels, these systems deliver low temperature, high output heating that performs exceptionally well in cold climates and high end homes.

WBI’s Radiantboard, Thermalboard, and EPS backed systems allow contractors to build radiant assemblies that are fast to install, energy efficient, and optimized for long term performance. For homeowners, hydronic radiant floor heating transforms comfort from a mechanical system into a daily experience.