How Radiant Heating Subfloor Panels Work and Why They’re Worth It

How Subfloor Panels Work for Radiant Heating

Radiant floor heating has become one of the most comfortable and efficient ways to heat a home. Instead of blowing hot air through vents, radiant systems warm the floor itself, creating steady, even heat from the ground up. The key to making these systems efficient and responsive is the use of radiant heating subfloor panels.

What Are Radiant Heating Subfloor Panels?

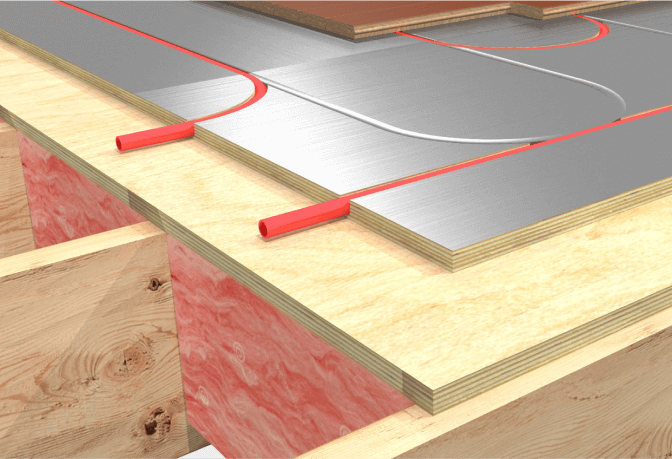

Radiant heating subfloor panels are engineered boards that hold and transfer heat from PEX tubing into the floor above. Each panel contains channels that precisely fit the tubing layout, allowing hot water from a boiler to flow evenly across the entire surface.

The top of each panel is faced with aluminum, which spreads heat quickly and uniformly. Beneath that, the core material—typically MDF, plywood, or OSB—provides structure and stability. Some panel types include an EPS insulation layer, which helps reduce heat loss into the subfloor and directs more warmth upward into the living space.

How Subfloor Panels Work

When warm water circulates through the PEX tubing inside the panels, heat transfers through the aluminum surface and into the floor covering above. This radiant energy warms the surfaces and air in the room evenly.

Unlike forced-air systems, radiant subfloor panels don’t rely on air movement. The result is a quiet, consistent, and comfortable warmth that doesn’t stir up dust or allergens. Because the entire floor becomes a large, low-temperature radiator, the system can operate at water temperatures much lower than baseboard or traditional heating systems, saving energy while maintaining comfort.

Why Radiant Subfloor Panels Are Worth It

- Faster Heat Transfer

The aluminum layer in radiant subfloor panels spreads heat more quickly than bare tubing in the floor. This means faster response times and fewer temperature swings throughout the day. - Lower Operating Costs

Radiant systems using subfloor panels can often operate with water temperatures 20 to 40 degrees lower than other systems. That reduces energy use and allows modern condensing boilers to run at peak efficiency. - Easy Installation and Design Flexibility

Subfloor panels can be installed over wood framing, existing subfloors, or concrete. They work in both new construction and remodel projects and can be covered with wood, tile, vinyl, or laminate flooring. - Improved Comfort

Even heat distribution eliminates cold spots and uneven room temperatures. Radiant floors also maintain humidity and air quality, making homes feel more comfortable at lower thermostat settings.

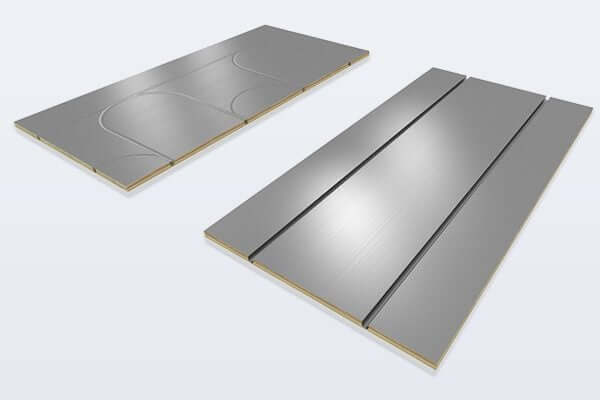

How WBI Panels Improve the System

WBI’s RadiantBoard and ThermalBoard panels are designed specifically for high heat transfer and durability. The dense core material provides stability and screw-holding strength, while the continuous aluminum surface ensures even heating. For installations over concrete or uninsulated subfloors, RadiantBoard EPS and ThermalBoard EPS include a built-in insulation layer that enhances efficiency and reduces downward heat loss.

By combining these panels with a properly sized boiler and zoning controls, homeowners can achieve efficient, consistent comfort in every room of the house.

Ideal Applications for Radiant Subfloor Panels

Radiant subfloor panels are ideal for:

- Homes with wood subfloors

- Remodels or additions where height is limited

- Projects where fast response and high comfort are priorities

- Installations over concrete using insulated panel options like WBI EPS panels

Are They Worth It? Absolutely.

While radiant subfloor panels cost more up front than basic tubing-only systems, they deliver greater comfort, efficiency, and long-term value. Homeowners typically see lower heating bills, improved comfort, and a system that performs consistently for decades.

When you factor in the energy savings, longevity, and comfort, radiant subfloor panels are one of the best upgrades you can make for your home.