Heating Concrete Floors: Pros and Cons of Radiant Systems and Why EPS Makes All the Difference

Concrete Radiant Floor Heating: What Works, What Doesn’t, and Why EPS Stands Out

When it comes to comfort, efficiency, and modern design flexibility, few systems compare to radiant heating. But as any contractor knows, not all radiant installations are the same. The substrate you’re working with, especially concrete, dramatically impacts system performance and installation workflow. Let’s take a closer look at the pros and cons of heating concrete floors, the differences between in-slab and above-slab radiant systems, and how using EPS-insulated panels can improve response time and overall comfort.

Why Contractors Choose to Heat Concrete Floors

Concrete floors have become a standard surface in residential and commercial builds because of their strength, durability, and design versatility. From polished basements to finished garages, shops, and main-level slabs, heating concrete floors offers several key benefits:

- Even consistent heat

Hydronic radiant systems distribute warmth evenly across the entire surface, eliminating cold spots and drafts common with forced air. - Long-term energy efficiency

Concrete’s mass stores thermal energy, maintaining steady temperatures and reducing cycling of the heat source. Over time, that translates to lower operational costs. - No visible ductwork or registers

Radiant systems keep the mechanical elements out of sight, freeing up valuable wall and ceiling space for design flexibility. - Quiet, low-maintenance operation

Once installed and properly balanced, a radiant system in concrete requires minimal maintenance and runs virtually silently. - Ideal for multiple flooring finishes

Concrete radiant systems work well under tile, vinyl, laminate, and stained finishes, perfect for both utilitarian and upscale applications.

The Downsides of Heating Directly in Concrete

While in-slab heating is time-tested, it’s not without its challenges. For contractors, understanding these drawbacks helps guide clients toward the best long-term solution.

- Slow response time

Concrete’s mass that helps retain heat also makes it slow to change temperature. Once heated, it’s steady, but it can take hours to reach target temperatures. That lag can frustrate occupants who expect fast comfort adjustments. - Limited control zones

Because the slab acts as a giant heat sink, fine-tuning temperatures in different rooms or zones becomes more complex. - Difficult access for repairs

Once tubing is buried in concrete, it’s essentially permanent. If there’s ever a leak or issue, there’s no simple way to service it without cutting into the slab. - Potential heat loss downward

Without proper insulation, radiant energy can bleed into the ground, especially in basements or on-grade slabs. Even with modern concrete mixes, conduction losses can be significant. - Timing with other trades

In-slab radiant requires coordination with concrete crews and curing schedules. Once poured, there’s no flexibility for changes.

The Modern Alternative: Above-Concrete Radiant Panel Systems

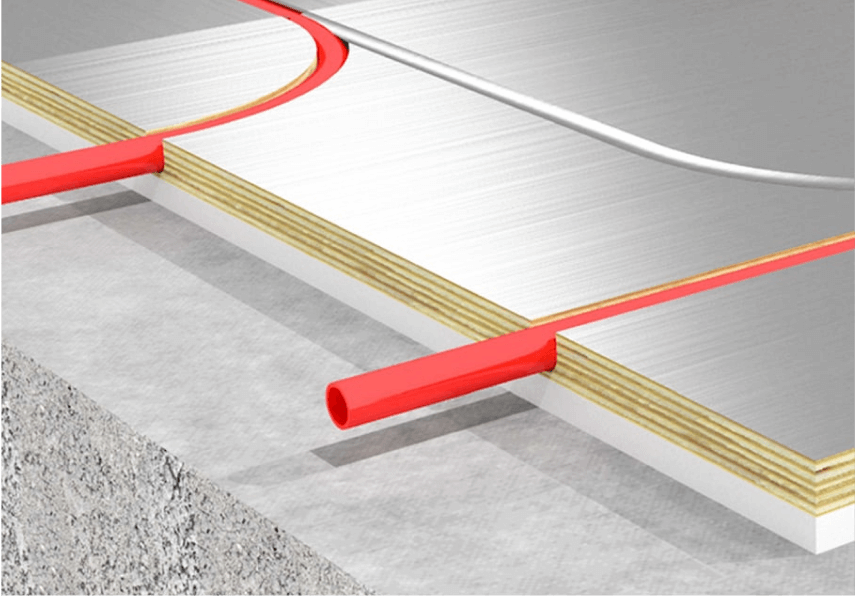

As radiant heating evolved, so did installation methods. Today, many builders are turning to above-slab radiant panel systems, which install directly over existing or new concrete surfaces. These systems use modular panels, often made from engineered wood or composite cores paired with aluminum and insulation layers, to create fast, efficient heat delivery without embedding tubing in the slab.

Key Benefits for Contractors

- Faster response times

Because heat doesn’t have to penetrate several inches of mass, above-slab systems warm more quickly. Rooms can reach comfortable temperatures in a fraction of the time. - Simplified installation sequencing

No need to coordinate with concrete pours, install panels after the slab is cured, even during remodels or retrofit projects. - Reduced downward losses with EPS insulation

When panels include an EPS (expanded polystyrene) backing, more heat is directed upward into the living space instead of being absorbed by the concrete below. - Lightweight and versatile

These systems can be used over basement slabs, garage conversions, or new builds. Panels cut easily and adapt to irregular floor plans. - Compatibility with finished flooring

Above-slab systems maintain low profile heights, allowing installation beneath tile, engineered wood, or luxury vinyl without significant elevation change.

Why EPS Backing Matters

EPS-insulated radiant panels are specifically engineered to address one of the biggest inefficiencies in concrete radiant systems: downward heat loss.

EPS (expanded polystyrene) provides high compressive strength with excellent thermal resistance, preventing energy from being wasted into the slab. More importantly for radiant performance, the insulation layer helps decouple the heating circuit from the concrete mass—meaning faster surface response and more consistent heat delivery.

In other words, with an EPS-backed system, the radiant energy is focused where it matters most: the room above.

Comparing System Types

| System Type | Installation Timing | Heat Response | Efficiency | Access for Repairs | Ideal Use Case |

| In-Slab Tubing | During pour | Slow | High, but losses downward | Difficult | New construction |

| Above-Slab Without Insulation | After pour | Moderate | Good, some losses | Easy | Retrofits with mild climates |

| Above-Slab With EPS Insulation | After pour | Fast | Excellent, low losses | Easy | Remodels, basements, or high-efficiency projects |

For contractors working in mixed climates or high-performance homes, that last option typically delivers the best balance of comfort, efficiency, and installation simplicity.

How EPS Radiant Panels Simplify the Build Process

Beyond thermal benefits, EPS-backed panels simplify several practical challenges for contractors:

- Reduced coordination with other trades, since no tubing or manifolds interfere with concrete work.

- Quicker dry-in schedules, allowing other finish trades to continue working while panels are installed.

- Lightweight handling, with panels easily cut to fit around plumbing penetrations and walls.

- Predictable performance, since the insulation and aluminum layer are manufactured to consistent specifications.

Systems that combine EPS insulation with aluminum-faced heat transfer layers also produce uniform surface temperatures, improving comfort and eliminating cold seams across floor zones.

A Practical Example: EPS Panels Over Concrete

For example, a 1,000-sq-ft basement remodel using EPS-insulated radiant panels can be completed in a few days with standard carpentry tools. Tubing channels are pre-cut, ensuring consistent spacing and heat distribution. After tubing is installed, the floor is ready for finished flooring, no waiting for a concrete cure cycle or worrying about tubing damage during pours.

Once operational, the system delivers a responsive, comfortable heat that adjusts quickly to thermostat changes, ideal for spaces that aren’t occupied full-time.

Product Spotlight

WBI has taken these concepts further with engineered panel systems designed specifically for concrete applications. Our EPS-backed radiant panels combine structural strength, precise tubing channels, and high-conductivity aluminum surfaces for optimized heat output. Available in multiple panel formats, they allow contractors to handle both remodel and new-build scenarios with a consistent, repeatable system.

Because they install directly over concrete with minimal elevation change, WBI panels offer an efficient solution where in-slab systems would be too slow or costly to modify. The integrated EPS backing directs heat upward, improving performance and reducing system run times, an immediate gain in both comfort and energy efficiency.

Final Thoughts

Heating concrete floors has always been a solid choice for comfort and energy performance, but above-slab systems have changed the game. By moving the heat closer to the surface and incorporating EPS insulation, contractors can deliver faster, more efficient, and more serviceable radiant systems, without the drawbacks of traditional in-slab installations.

Whether you’re designing for a new build, basement finish, or retrofit, understanding how EPS-insulated radiant panels perform over concrete can help you offer clients a better, more responsive heating experience while simplifying your own installation process.