Great Ideas for Making Elegant Designer Cement Slabs

Beautiful Designer Cement and hot water radiant floor heating are natural partners. Any time a concrete slab is utilized, hydronic tubing can be embedded in it to provide the comfort of radiant heat. New ways of finishing cement mean the concrete itself can be a beautiful floor in itself. This makes for a highly conductive, beautiful floor. Without needing less conductive floor coverings like wood and carpet, it can be operated at lower water temperatures, saving energy and costs.

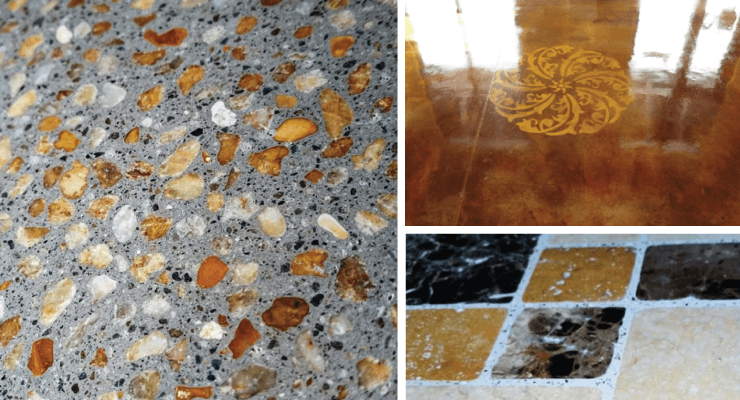

Courtesy Deco-Pour

Courtesy Deco-Pour

Below are descriptions of how these methods are done and visual examples of decorative cement contractors’ work. I have featured the work of 3 long-time contractors and innovators in this field. Often, many of the approaches below are combined for complex effects. There are many other talented contractors who can be found at www.concretenetwork.com.

Adding Color to Concrete Slabs

Slabs can be colored by admixing pigments at the cement plant. These color the whole slab and take a lot of pigment, usually less costly, common earth and mineral pigments. Stains and dyes are applied to the surface of slabs. Stains can be applied to create marbled effects. Dyes can tint the surface and are more uniform. Experienced contractors often have developed and perfected their favored effects. Some contractors use a “dry shake method” to vary the colors of the concrete with pigments and stains. The concrete is usually then sealed with a durable, clear top coat.

Coating Concrete

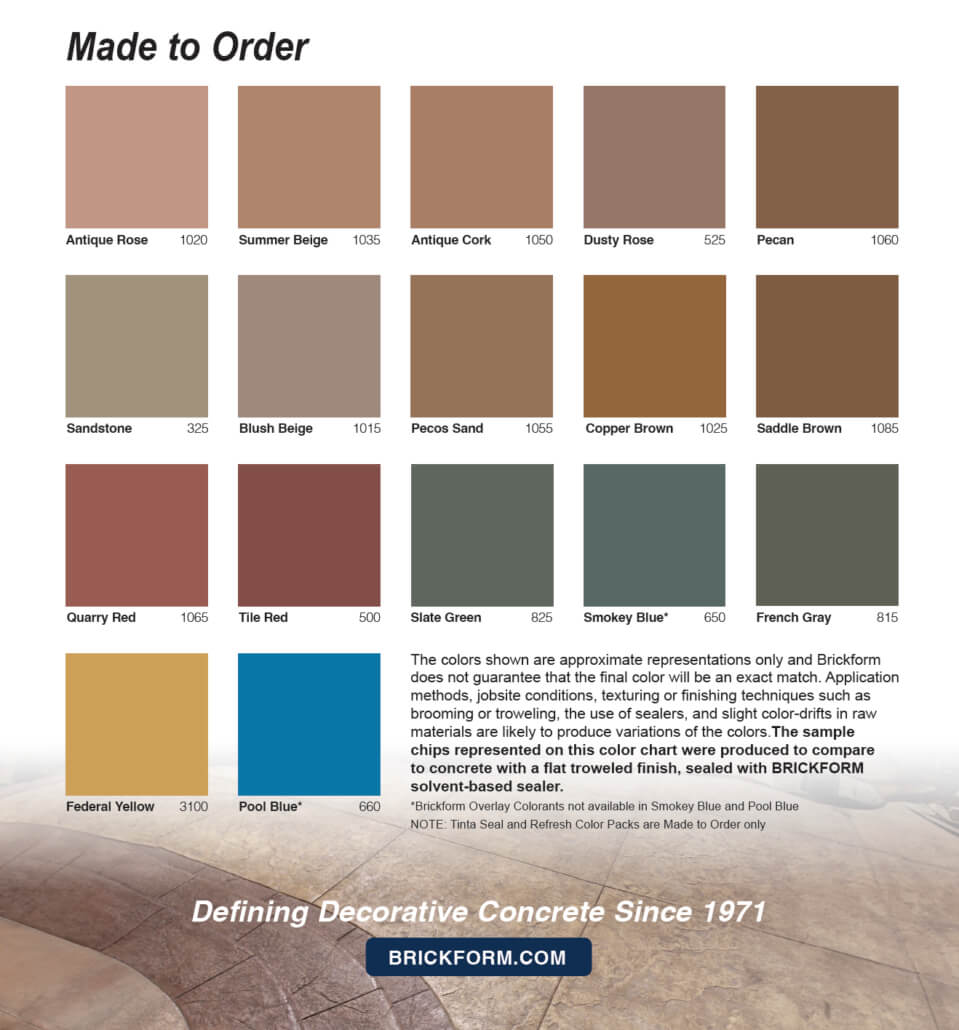

Color Charts Courtesy Solomon Colors Inc.

Many contractors have adapted by using a coating layer of concrete to allow for leveling and being able to add specialized pigments for color, stone fragments, or even bits of sparkling glass. These overlays are often around ½” thick and use specialized self-leveling cements. They are then polished and sealed. The color charts above give you examples of what colors are possible.

Ideas for Stenciling Designer Concrete Slabs

Stenciling often brings out the artist in a talented concrete contractor. Concrete is first polished. The stencil is done in a process that is similar to silk-screening, where a separate vinyl stencil is fabricated for each color and applied to the floor. Penetrating dyes are applied to areas not covered by the masking, which tint the concrete. Once the dye is dry, the masking is removed, and the masking for other colors is applied in sequence until the image is complete. After completion, it is given a durable, clear top coat.

Courtesy of Decorative Concrete and Color, Aurora, CO

Image Courtesy Decorative Coatings and Concrete Company

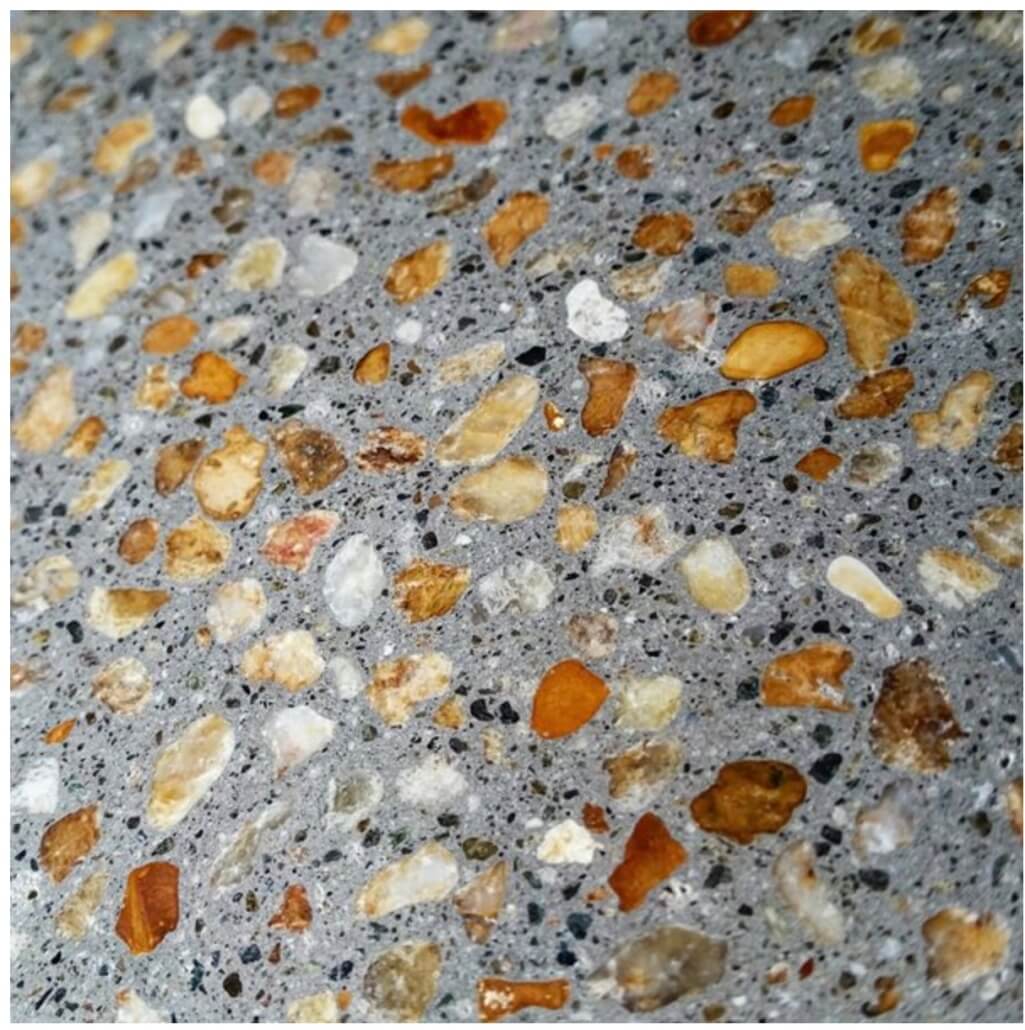

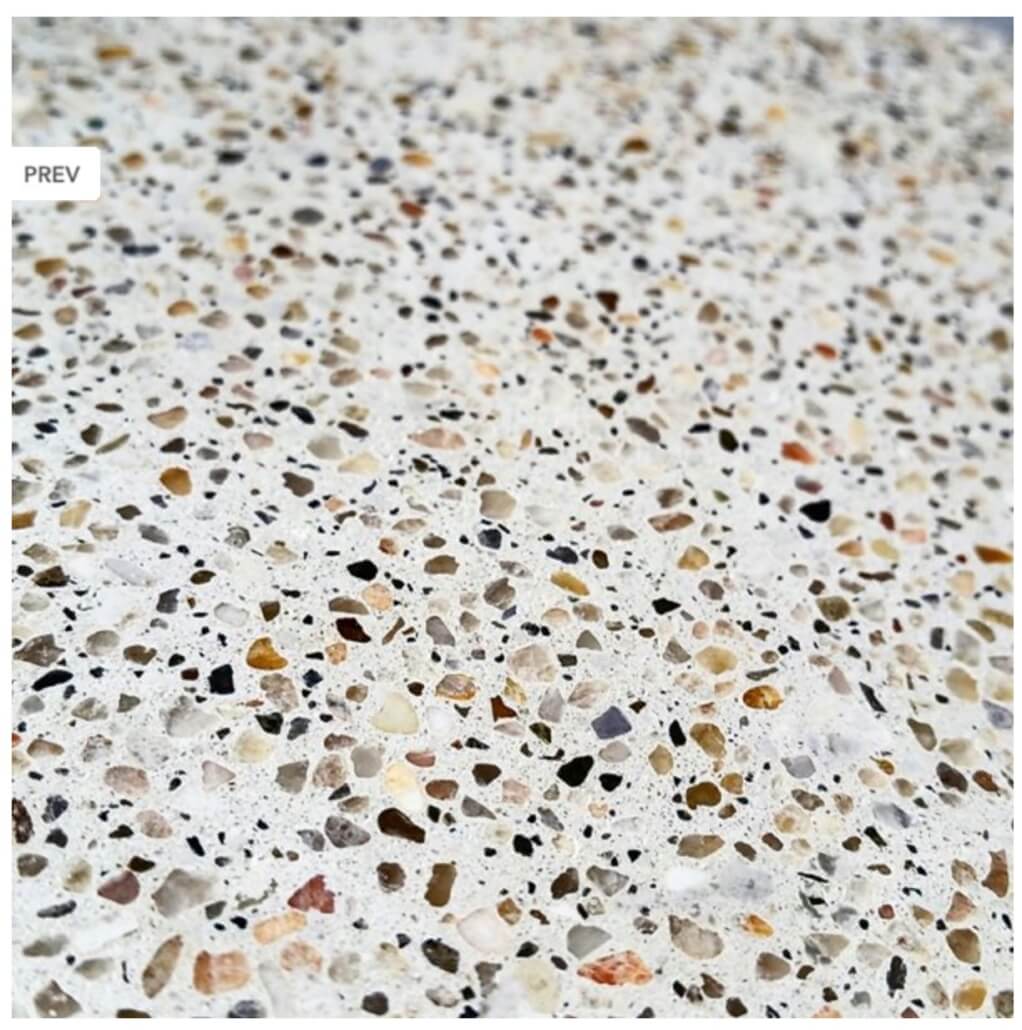

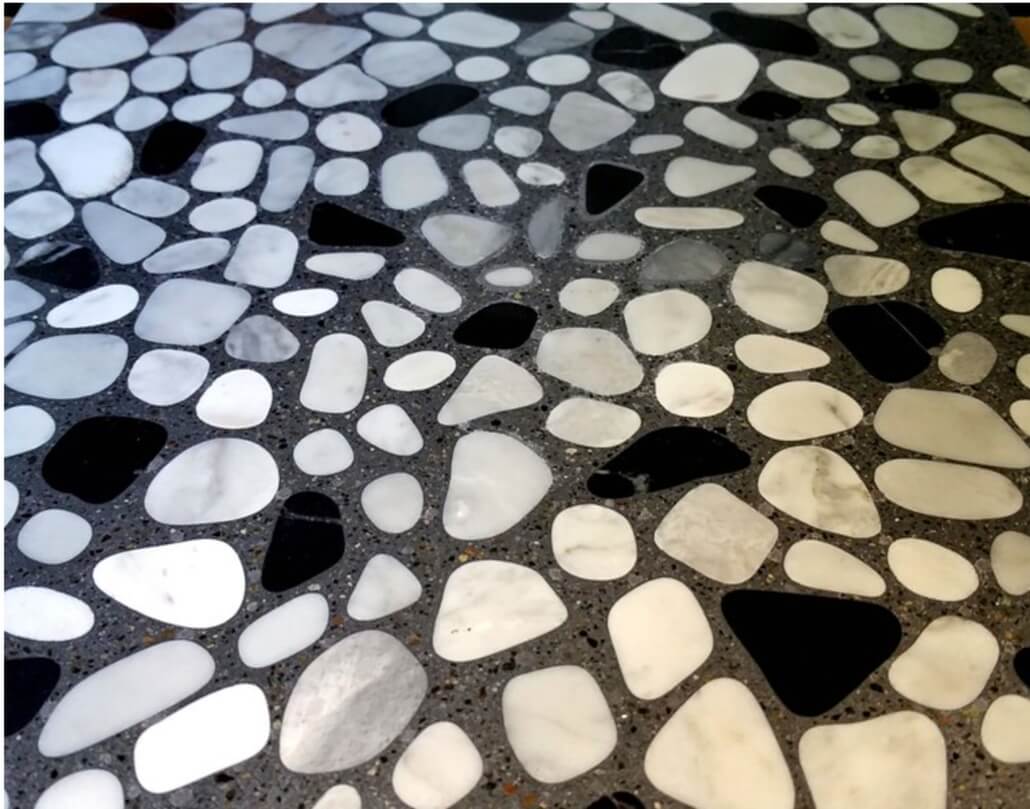

Terrazzo Cement

In the context of this article, terrazzo is usually a concrete composite material used for flooring and wall treatments, made by embedding small pieces (chips) of marble, quartz, granite, glass, or other suitable materials into a cement that is then ground or polished. Once it hardens, the surface is ground and polished to a smooth, often shiny finish, and a durable sealant is applied. It can be precast in pieces or on-site. It is often used for high-traffic commercial space, but is now being used in high-end homes. It is very durable and decorative.

The origins of the word Terrazzo are interesting and revealing. Starting in the mid-1500s in Venice, marble chips left over from sculptures were used to create inexpensive flooring for terraces and walkways. They would set the chips in clay or mortar and then polish the surface. Similar surfaces were found in the floors of the Roman town of Herculaneum when Mt. Vesuvius exploded.

“VENETIAN” VARIANTS THAT INCLUDE MORE MATERIALS THAN TERRAZZO

The origin of the word Terrazzo is interesting and revealing. Starting in the mid-1500s, in Venice reused marble chips left over from sculptures was used to create inexpensive flooring for terraces and walkways. They would set the chips in clay or mortar and then polish the surface. Similar surfaces were found in the floors of the Roman town of Herculaneum when Mt. Vesuvius exploded, so clearly similar things had been done earlier in other places.

Stamped Concrete Slab Designs

Contractors can buy Stamps or multi-piece sets of stamps that emulate the look of many other materials. For example, a set of stamps that can make concrete look like slate, Saltillo tile, brick, or many other looks. These stamps are used at just the right time as the concrete is hardening.

Stamped image courtesy of Brickform, a Division of Solomon Colors. Watch a video about Brickform and Solomon Color products.

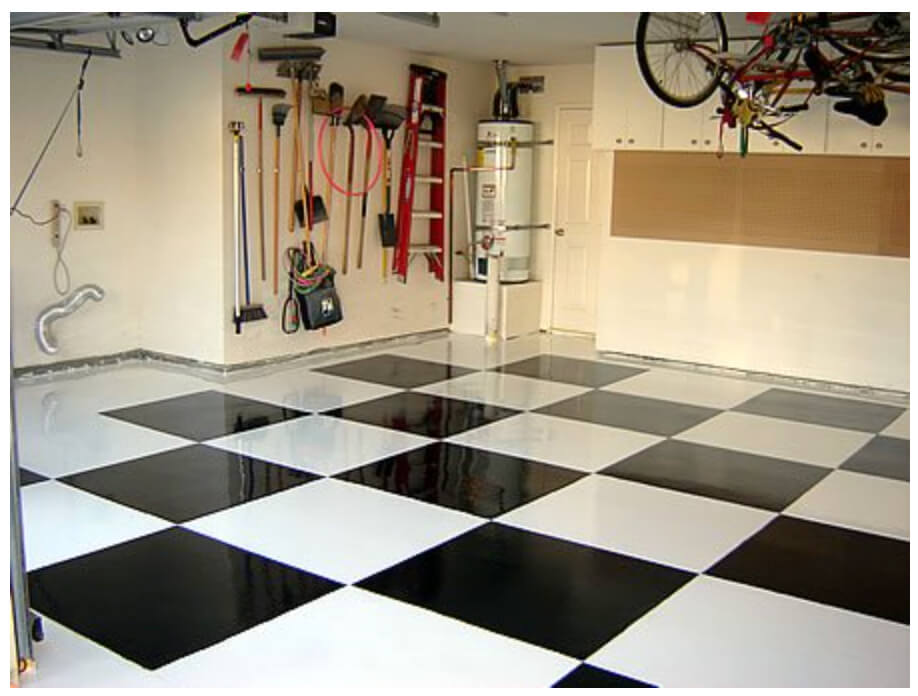

Specialized Coatings for Garages & More

Strong and durable coatings are often used in garages where a durable, easily cleaned coating is desired. Since PEX pipe can be damaged by various petrochemical products, keeping the surface of a garage or workshop well sealed is very important. Various epoxy products are available for this use.

Other Types of Decorative Concrete Finishes

These include specialty troweling, scratching, and chemicals.

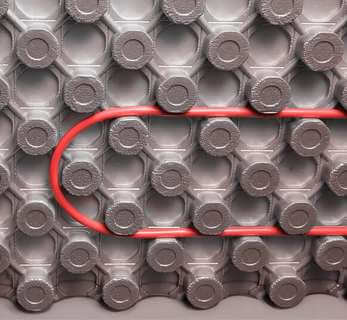

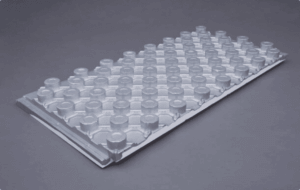

Pour your Decorative slabs on Insulheat Foam

Warm Brothers Inc. has the ideal insulating product that will make your decorative concrete slab more energy efficient and quicker and easier to install. It is called Insulheat™.

Insulheat™ is the ideal way to pour an insulated radiant slab.

INTERESTING RESOURCES:

History of Terrazzo in Venice, Italy

ABOUT THE AUTHOR

Hoyt Corbett

Partner, Warm Brothers Inc.

Hoyt has been involved with hydronic heating since the early 1990’s and developed and sold a national brand of radiant floor heating that was acquired by Uponor. Subsequently, Hoyt was Associate Director of the Radiant Panel Association, the industry trade group.

He’s produced extensive technical writing on radiant floor heating, writing several major national hydronic vendor’s radiant heating design and installation manuals as well as founding and publishing The Radiant Flooring Guide.