Hydronic Radiant Floor Heating Panel Types and Thermal Inertia

This blog is designed, in a commonsense way, to explain how different radiant panel types respond at different rates when charged with warm water. It will explore the applicable uses of different types of hydronic radiant panels and applicability of different controls to each type.

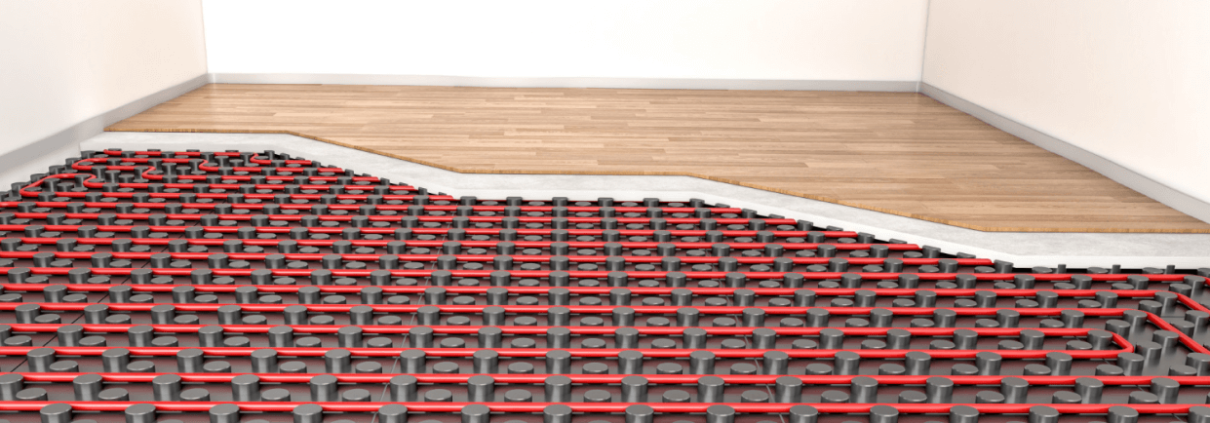

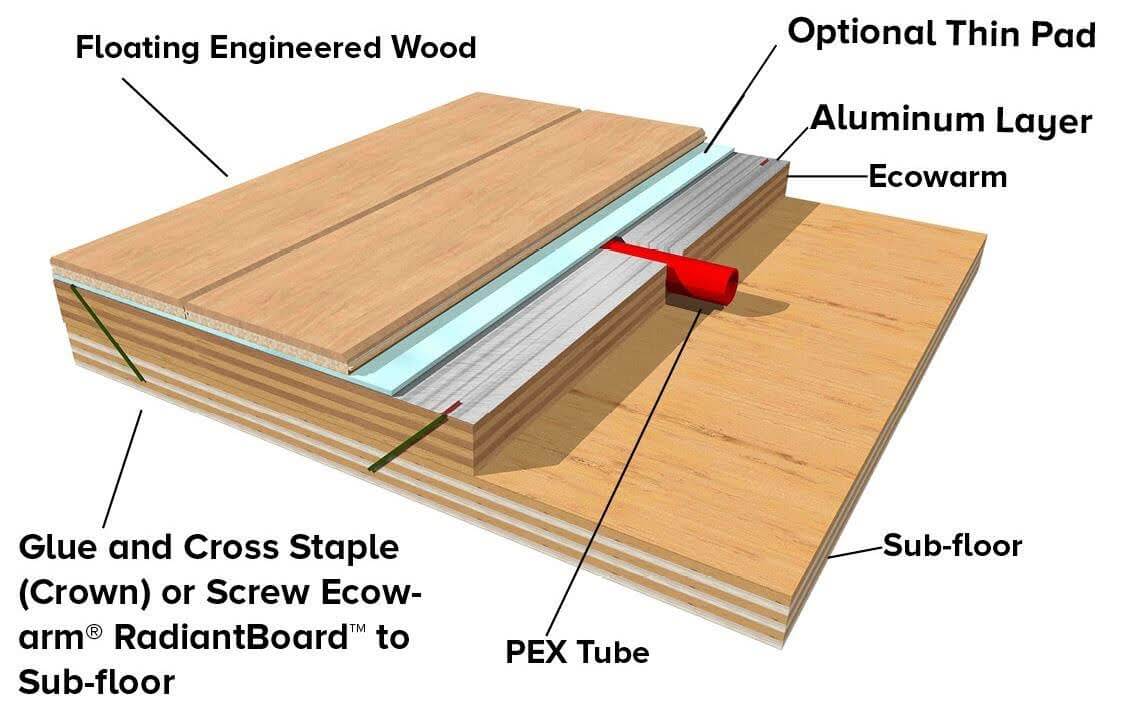

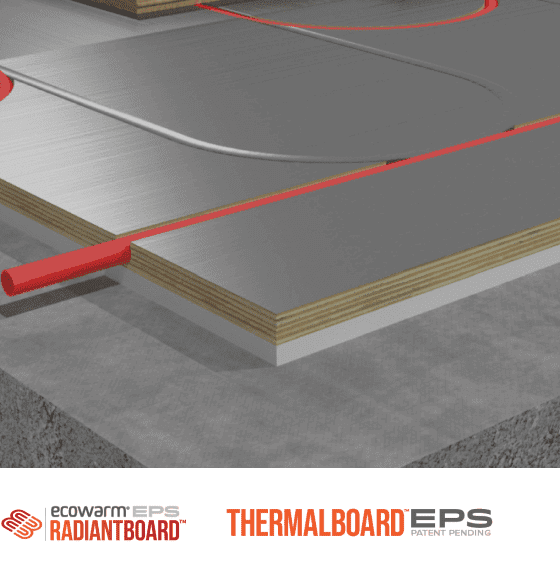

Example of a high mass hydronic radiant panel system in a slab followed by a low mass example attached to a subfloor Followed By An Example of A Low Mass, Low Thermal Inertia Radiant Panel System.

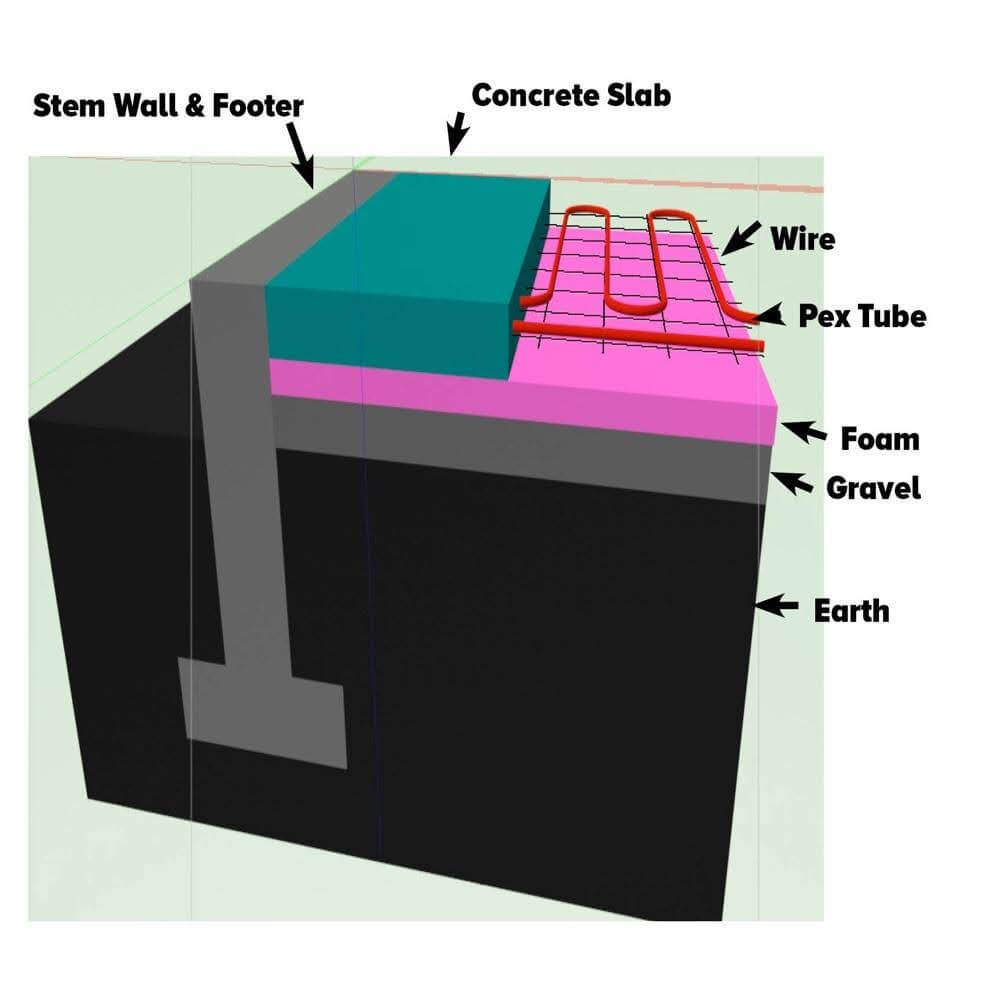

Radiant floor heating hydronic panels using a slab have a lot of thermal mass that must heat up or cool down to counter-act changing temperatures in a home or a building. A large mass of relatively dense concrete conducts the heat from the pipes to the surface which usually includes floor coverings from where it then radiates heat to the room.

Low mass, low thermal inertia panels are usually made by combining a low mass strata with a modest thickness of a very conductive material. Properly designed they heat up and cool down quickly. The high and low mass systems each have their place, but the differences are worth learning about for anyone contemplating or living in a radiantly heated home.

For clarity, hydronic radiant panels used for hydronic heating transfers heat predominantly by radiation once the heat gets to the surface of the panel. Due to where it is used, the proportion of heat provided by a convective loop in a room is different for floor, wall and ceiling applications. All rooms are individual circumstances, but radiant floor heating panels may be 58% radiant and 42% convective, radiant wall panel wall may be 75% Radiant and 25% Convective while ceilings may be may 92% radiant and 8% convective.

While the effects of placement of hydronic radiant panel are interesting, more important for this article is how fast a system responds to heating up and cooling down which is related to the panel’s thermal inertia. In general low mass systems respond faster (heat up and cool down) faster provided they are conductive enough to move the needed amount of energy to the surface of the panel and then to radiate and heat the space. This is also termed the thermal inertia of the hydronic radiant panels or radiant board.

In the context of hydronic radiant floor heating systems, thermal inertia can be described as the radiant panel system’s ability to store and slowly release heat. It is the resistance of the panel structure or the materials within it, such as concrete, wood aluminum and a variety of floor coverings to temperature changes. High mass radiant panel systems as exemplified by concrete slabs heat up slowly and cool down slowly. To affect changes in the surface temperature of such a system requires either heating up the whole mass of concrete to raise its temperature or waiting while the whole mass cools down. In a low mass hydronic radiant panel, when properly designed, will respond much faster both to heat up and cool down. Both types of systems have implications for control and application.

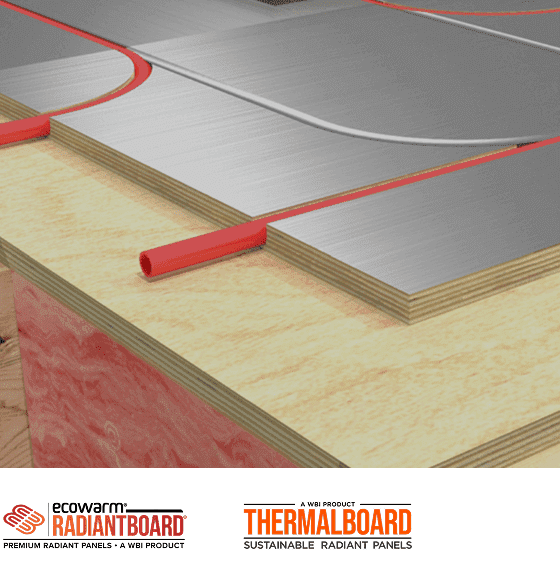

In my early experience as a contractor there really were no “low mass, low thermal inertia” systems on the market. Hence I had a lot of experience with high mass, high thermal inertia systems. Later as part of this company, Warm Brothers Inc. We developed and patented a low mass, non structural radiant board called Thermalboard which is part of the growing portfolio of radiant boards, that our company now makes and sells. So, I have a lot of experience with both high and low mass radiant systems and hope my experiences will be helpful.

Radiant Heat Panels To Meet Most Radiant Heating Applications

Our radiant panels deliver efficient heating across multiple applications. We even have Low Mass radiant panals with EPS bonded to the bottom of panel for use over uninsulated concrete slabs. Visit www.wbiwarm.com to see these products. One of my early projects was installing radiant floor heating in a two story building housing a dance studio and office on the ground floor and an office an apartment on the apartmentn the second floor.

Both floors can be described as high mass high thermal inertia systems. The first floor was a slab on grade. They were installed as shown below. The first floor installed with foam steel tubing and cement as shown. In addition there was a floating floor above the slab mounted on 2”x2”x2” foam cubes. This allowed the floor to flex to help prevent injuries of jumping up and down on hard floors. It worked by the concrete radiating heat to the suspended plywood floor which in turn radiated it to the whole room. Since the studios were not used 24 hours a day there was initially, a desire to put a significant set-back when it was not used.

The disadvantages of a high mass system such as this is that it took about four hours to heat back up due to the amount of energy it took to charge the system back. And if the schedule of use changed without it having been anticipated, lightly clad dancers arrived and were cold. The second floor had somewhat less mass with tubing stapled to the subfloor and covered by 1-1/2” of six sack pea gravel mix of cement. It required a second bottom plate and had a similar recovery time profile. Later thermostats that had a learning “adaptive recovery” feature got better at timing setbacks. However, with time the dance studio adopted a “Set and Forget” approach where they did not use set-backs. This was not because it could not be set up with the right control to do setbacks but because the set-back schedule was not easily predicted.

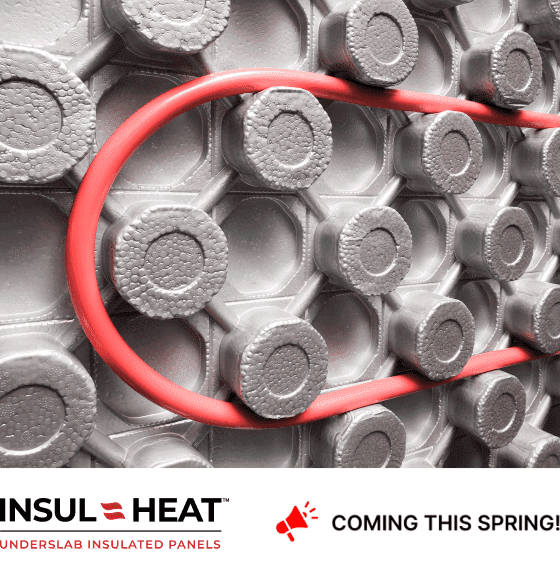

The time lag and thermal fly wheel aspects of slabs on grade make them easiest to control and use in climates with modest temperature swings, basements where temperature swings are moderated by stable ground temperatures, houses with overhangs that minimize solar gain, garages with few windows and in climates where with deliberate solar designs, the thermal mass of a slab can help store and redistribute solar gain. New technology has now made controlling slab-based hydronic radiant panels more reliable and efficient. And our newest panel, InsulHeat™ for use under slabs, has made installing a hydronic slab cost effective. . Here is a link to previous blog on the product: https://wbiwarm.com/blog/hydronic-radiant-floor-heating-in-concrete-slab/

Later Warm Brothers inc. patented Thermalboard™ a low mass, low thermal inertia product which has since been followed by Ecowarm® Radiantboard™ and many others. These systems have many advantages. Simply put they can quickly go through the stages of a radiant panel where it absorbs heat and releases it with out a long period charging a mass getting it to the point where it will release heat.

Over Raised Floor Subfloor

Over Concrete Slab

Optimizing Hydronic Radiant Panels with Outdoor and Indoor Reset Controls

Both types of systems benefit from good controls. An outdoor reset control which adjusts water temperature according to the weather can get the BTU’s being supplied to the heating system a close match tom the heating demand which reduces cycling, prolongs mechanical products and promotes even temperature change. They are very helpful in controlling slabs since once the right curve is found such a control is keeps temperature swings in a high mass system within a range that the fine tuning is then done by the thermostats.

In the low mass board systems we sell, use of outdoor reset controls has a similar benefits and, in particular really helps bring traditional wood flooring systems through temperature changes slowly. The low mass boards we sell have a particular benefit that the quick recovery of the system means many different setbacks and temperatures can be programmed in a day. So if you like the house warm when you wake up, cool while you are gone during the day, warm again for the evening and cool for sleeping a low mass product will easily do that.

Unlike a slab system, if an unexpected guest arrives and you need to quickly heat up the guest suite you can do that. Again thermostats that have adaptive recovery logic will make it work better. Maybe a way to think about it is that its has a bit of AI enabling it to get better at controlling your house. Properly controlled high mass systems can be very stable but are just hard to change quickly. There are climates in the United States that have a heating and cooling load in the same day….desert climates and the central valley of California come to mind. Paying to cool a high mass system that you earlier in the day paid to heat makes absolutely no sense and hence should utilize low mass radiant panel systems.

There are also Indoor Reset Controls which alter the watger temperature based on room temperature. They do not take into account the effects of dramatic weather temperature changes the way an outdoor reset control does. This can be a problem with high mass systems where if the oudoor temperature drops dramatically it will show only later in the room temperature dropping putting a slower responding system behind in catching up.

There are also floor and slab sensing thermostats and some ones that can control both. Usually, the floor sensor is essentially a safety for floor coverings that have a maximum allowed temperature.

ABOUT THE AUTHOR

Hoyt Corbett

Partner, Warm Brothers Inc.

Hoyt has been involved with hydronic heating since the early 1990’s and developed and sold a national brand of radiant floor heating that was acquired by Uponor. Subsequently, Hoyt was Associate Director of the Radiant Panel Association, the industry trade group.

He’s produced extensive technical writing on radiant floor heating, writing several major national hydronic vendor’s radiant heating design and installation manuals as well as founding and publishing The Radiant Flooring Guide.

Call Hoyt at 206-369-1458, 8am to 5pm PST

or

email him at: hoyt.corbett@warmbrothersinc.com