Modified vs. Unmodified Thinset: What to Use Over Radiant Floor Heating Systems

When installing tile over a radiant floor heating system, one critical decision can make or break the performance of your project: choosing the right type of thinset mortar. The debate between modified vs. unmodified thinset often causes confusion—especially when radiant heat is involved.

In this guide, we’ll explain the difference between the two, when to use each, and how to ensure your tile stays firmly in place above your heating panels. This is particularly important when working with high-performance panel systems like aluminum-clad radiant boards or EPS-backed panels, where adhesion and flexibility are key.

What Is Thinset Mortar?

Thinset is a type of adhesive mortar used to bond tile to the substrate. It’s typically made from cement, fine sand, and a water-retaining agent like cellulose.

There are two primary types:

1. Unmodified Thinset (Dry-Set Mortar)

- Contains no added polymers

- Requires only water for mixing

- Relies on hydration of cement for strength

2. Modified Thinset

- Includes polymer additives for flexibility and adhesion

- Typically stronger and more flexible than unmodified

- Can be mixed with water or a latex additive (depending on formulation)

Why Thinset Type Matters with Radiant Floors

Radiant heating introduces two unique challenges for tile installations:

- Thermal expansion and contraction of the floor and substrate

- Moisture sensitivity of some subfloor or panel materials

Choosing the wrong thinset can lead to:

- Cracked grout lines

- Tile delamination

- Movement between layers that compromises the finish

Industry Standards and Recommendations

According to the Tile Council of North America (TCNA) and ANSI standards, both modified and unmodified mortars can be used over radiant systems—but the product must be approved for use over heated floors.

Tip: Always look for ANSI designations on your mortar bag:

- ANSI A118.1 = Unmodified thinset

- ANSI A118.4 / A118.11 = Modified thinset (with improved adhesion and flexibility)

Which Should You Use?

The answer depends on your radiant panel type and your flooring material.

Use Modified Thinset When:

- Installing tile directly over aluminum-clad radiant panels

- Applying over cement backer board or crack-isolation membranes

- Your tile is porcelain, stone, or large format

- You need extra flexibility to accommodate thermal cycling

Example: Modified mortars are ideal when tiling over Radiantboard or Thermalboard EPS, as their aluminum surface demands a strong bond and thermal resilience.

Use Unmodified Thinset When:

- Your tile manufacturer specifically requires it (especially with certain membranes)

- You’re using a latex additive separately (added to mix)

- Working with uncoupling membranes like Schluter® DITRA (unless otherwise directed)

Be cautious: Some uncoupling membrane manufacturers void warranties if modified mortar is used between the membrane and porcelain tile.

Surface Prep Is Critical

Regardless of which thin set you use, proper surface preparation is essential:

1. Clean the Substrate

No dust, oil, or debris should remain on the surface.

2. Dry Fit Tiles First

Ensure alignment before spreading mortar.

3. Use the Correct Trowel Size

Typically a 1/4″ x 1/4″ square notch for smaller tiles, 1/2″ notch for larger formats.

How to Tile Over Radiant Heating Panels

The method varies slightly depending on your panel type.

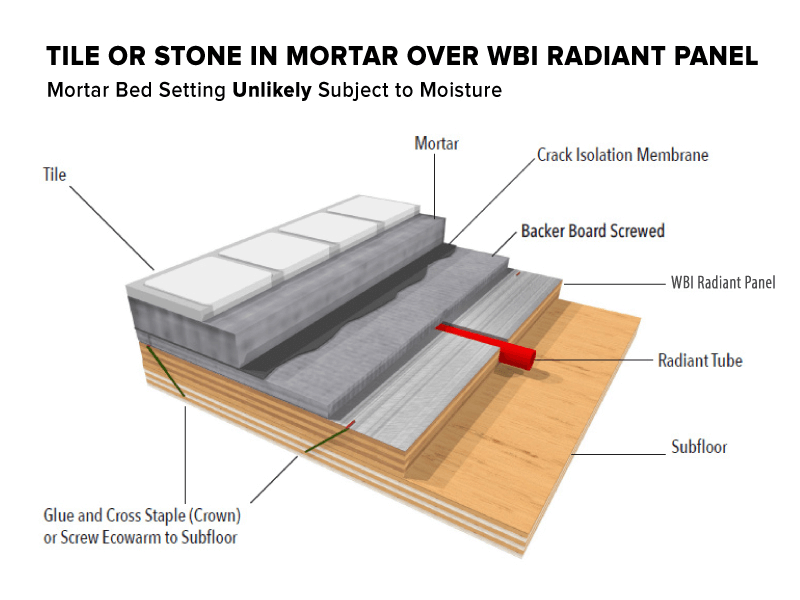

1. Over Grooved Aluminum Radiant Panels (e.g., WBI ThermalBoard)

- Install a layer of cement board or uncoupling membrane over the panel

- Use modified thin set to install the tile (ANSI A118.4 or A118.11)

- Allow proper curing time (minimum 7 days) before activating heat

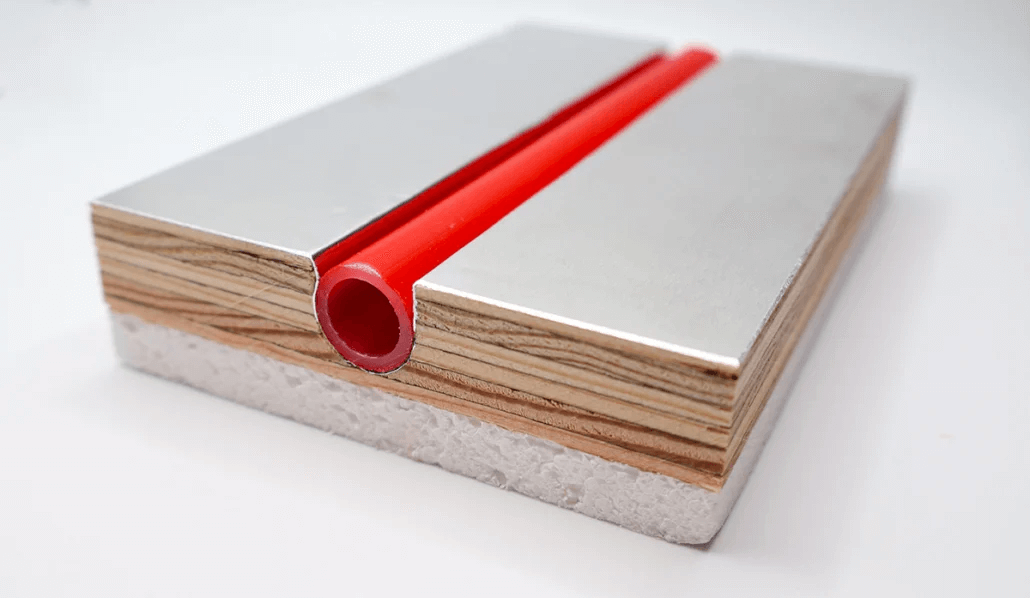

2. Over EPS-Backed Panels (e.g., Thermalboard EPS or Radiantboard EPS)

- Apply modified thinset directly over the embedded cement board or decoupling membrane

- Ensure no direct exposure of EPS to thinset—cover with approved underlayment

- Cure before using radiant system

Note: Products from Warm Brothers Inc., like Thermalboard EPS, include panel options that integrate aluminum and insulation for optimized performance under tile—but they must be installed with proper tile layering to avoid damaging the EPS core.

Common Mistakes to Avoid

Using standard mastic adhesives (not rated for heated floors)

Skipping decoupling membranes in high-movement areas

Activating the radiant system before the mortar and grout have cured

Applying thinset directly to raw EPS foam

When in Doubt, Check with the Manufacturer

Whether you’re using Schluter®, LATICRETE®, MAPEI®, or another brand of mortar or membrane, always check:

- Product data sheets

- Heat compatibility

- Recommended pairings with radiant systems

And don’t forget to verify that your thinset can handle thermal cycling, especially if your floors will be exposed to frequent temperature changes.

Summary: Modified Is Usually Better—But Always Confirm

In most radiant tile installations, modified thinset is the better choice. Its superior bond strength and flexibility make it ideal for heated floors, especially over aluminum surfaces or when large format tiles are involved.

However, always check:

- Your tile specs

- Underlayment requirements

- Radiant panel surface material

This will ensure a long-lasting, crack-free installation.

A Smart Installation Pairing

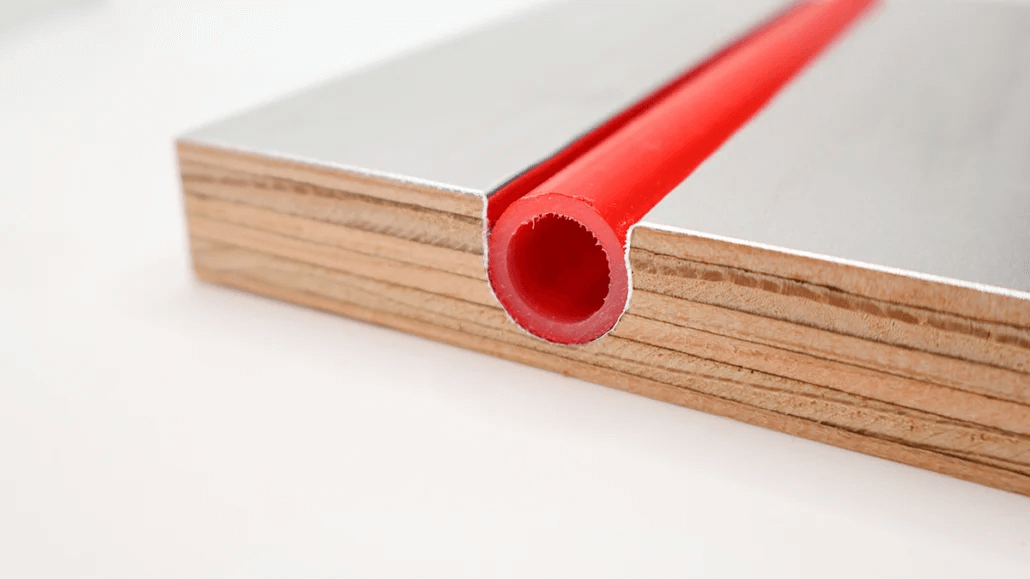

While this article focuses on mortar selection, it’s worth noting that Warm Brothers Inc. designs radiant heating panels specifically with tile installations in mind. Their ThermalBoard EPS™ system includes:

- Aluminum-clad surface for high conductivity

- EPS backing for insulation

- Compatibility with ANSI A118.4-rated mortars

These panels support smooth tile installs when paired with proper underlayments and mortar. Explore more at WBIWarm.