Radiant Heated Floors: Comfort You Feel, Efficiency You Trust

Radiant Floor Heating: Comfort Built to Last

There is a…

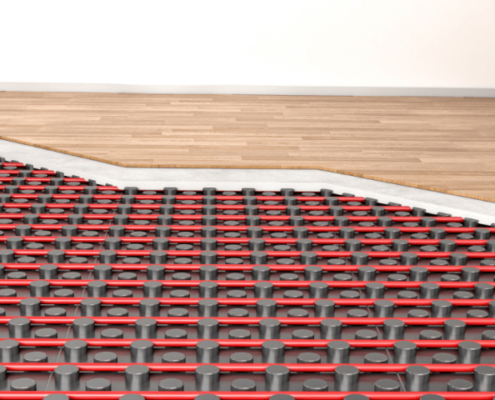

Radiant Heating Panels: The Foundation of an Efficient Radiant Floor

The Key to Efficient Radiant Floors

Radiant heating panels…

Radiant Floor Heating: Comfort You Feel With Every Step

Radiant Floor Heating That Warms Every Step

It is the middle…

Concrete Radiant Floor Heating: Panel-Based Systems vs In-Slab Systems

Radiant Floor Heating Over Concrete: Panel Systems vs In-Slab…

Radiant Floor Heating in New Construction: The Complete Guide

Radiant floor heating has become one of the most attractive…

Hydronic Radiant Floor Heating: The Ultimate Guide for Efficiency and Comfort

Hydronic Radiant Floor Heating Guide for Efficient Home Comfort

Hydronic…