In Search of the Ideal Hydronic Radiant Floor Heating Control

There’s nothing like beautifully calibrated hot water radiant floor heat to bring comfort to your spaces or home. In my mind, the ideal control system for hot water radiant floor heating would have the following features: It could be configured and its parameters input, remotely or on site, be enabled to learn its own entire environment and then automatically adopt the most efficient way to run the system in order to save energy and maximize comfort. With the advent of artificial intelligence this sounds reasonable, but where are we with this?

To explain my first requirement, that such a control strategy should be easy to configure both remotely or on site, let me digress into my past experience. In the late 1980s and early 90s I owned and ran a specialty radiant floor heating installation business in the Puget Sound area of Washington state: “Thermal Renaissance”. The idea being that it was a newer and better way to heat homes than forced air, or the older radiant floor heating systems that used copper rather than modern plastic tubing such as PEX.

At Thermal Renaissance, we installed a large number of systems, mostly, but not all, in nice waterfront homes. But as the map of Puget Sound shows, below, getting to those jobs always required driving around waterways and water bodies, taking ferries across the Sound to its many islands, or finding and taking bridges to reach a site. The price of being a specialty contractor was that you took the jobs where you found them. For most of our jobs, 1/3 to 1/2 the labor hours were in travel time. As you can see from the map below, the coastline is rugged, with many peninsulas and islands: we did projects or multiple projects on most of them.

During the latter period of my Thermal Renaissance era, Tekmar had the most sophisticated control products, but these were complicated to set up correctly, and we learned to dread the frequent eventuality of an owner deciding to go into the mechanical room and start spinning dials and pushing buttons. This inevitably resulted in another long and inconvenient trip to correctly reconfigure the customer’s controls, often at a time we were busy elsewhere. It even spoiled one Christmas Day for me and my family! Hence, my advice to use controls that can be logged into remotely.

Map of Puget Sound in Washington State

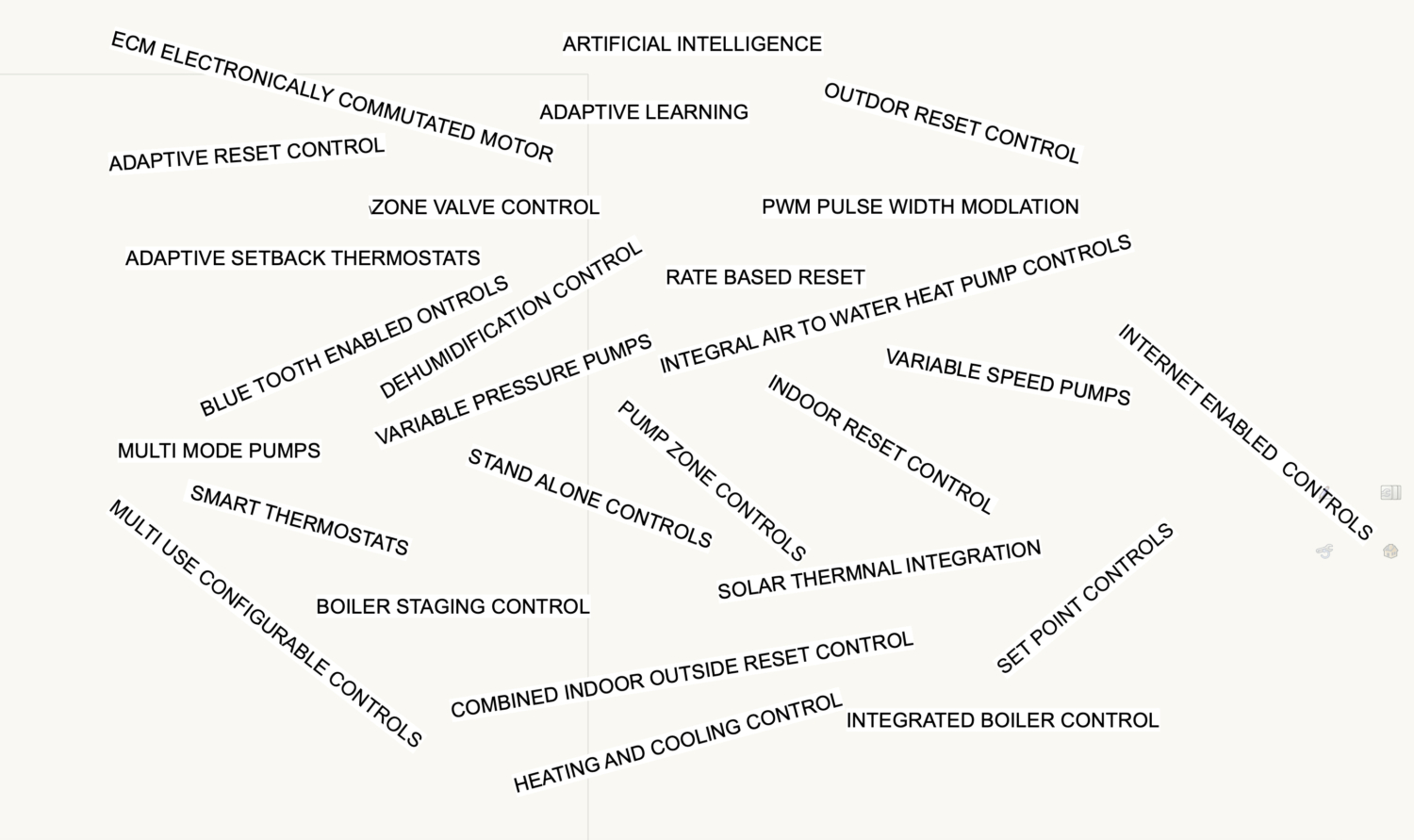

So now, in thinking about an ideal control system, as proposed above, that could learn and perfect the efficiency and performance of the whole system… where are we in the progression to such a possibility? If you look at the below word salad of candidate components of such a control system, you see hints that most of existing system components are already incorporating some adaptive behavior we associate with the promised future power of artificial intelligence.

Components are getting smarter, and some vendors are connecting more of them in increasingly inclusive ways. But so far, we still lack the ability of widely separated components to create a control system that self-learns its own environment and perfects itself in response. But many elements and trends are leading us toward this future. A few examples follow the word cloud below.

Word Cloud by Author

Trend 1: Individual Components Getting More Functions

Almost all individual hydronic components are gaining added functions and added “intelligence”. This has gradually been going on for longer than we realize. One of the first ideas was to add adaptive intelligence to set-back capable thermostats. This means that if a hydronic heating system is set back to a lower temperature at nighttime, the adaptive setback thermostat will get better at understanding or “adapting” to the required lag times it takes to set back the heat to the required lower temperature, as well adapting to (getting better at) predicting the lag time required to bring the system back up to daytime temperature.

Today, some thermostats have added “intelligent” features such as the ability to communicate—often wirelessly—with other thermostats and a controller. This allows for new efficiencies in comfort control. For example, the control monitors and finds from the thermostats the highest demand radiant heating zone, adds input from the outdoor temperature and, considering both, runs the system making complex decisions on how to fire the boiler most efficiently.

Today’s smarter pumps, such as Grunfos and Wilo, in particular, have added pumps with many new, easily programmable modes of operation. These “smart pumps” contribute to making the radiant system run more efficiently, and, when programmed correctly, reduce the consumption of electricity: when programmed correctly, they run just sufficiently to meet demand. Here’s the component “word salad” I mentioned above, each word relating to components that are now evolving toward greater functionality.

But again, where are we with my dream hydronic control system where, once all the components are connected, and a very few parameters set, the control then learns its environment and runs itself by means of its programmed intelligence? For this to happen, each component will truly have to communicate with the central control which needs to be capable of adjusting to each component and with the intelligence to do so. For now, we are still mostly assembling components that, when their collective functions are aggregated, provide excellent overall performance at the expense of complexity and knowing how to assemble and program all the parts.

But here is a product others are busy emulating that comes much closer to a “smart” boiler. For a number of years, most condensing boilers have routinely come with outdoor reset capabilities, but the Alta boiler from US Boiler Products has added 2 newer twists: a “Rate-Based Reset” continually using flame ionization information to adjust the flame. The Alta’s rate-based temperature reset, means it adjusts its firing rate based on supply and return water temperatures, rather than relying on an outdoor reset sensor.

This (Alta) method assesses environmental conditions, indoors and out, and continually adjusts the boiler’s operation for comfort and efficiency using information it learns from supply and return sensors, as well as from run rate and times. With the addition of advanced flame control the two control features from an installer’s point of view, the Alta has several “Set and Forget” attractions. The installer simply programs the highest water temperature a radiant system might need, the boiler initially ramps up to that temperature, then begins ramping downward until it is continually equilibrating the water temperature, boiler turn-down and blower speed.

The boiler has a 10-to-1 turn down. The argument for rate-based reset is that it is less likely to be fooled by changes due to wind, variable sunlight exposure, etc. So, while it does meet my hopes for a control that, once set up, learns and adjusts itself, it does not currently allow remote adjustment over the internet. In addition to its onboard rate-based reset, the adaptive flame ionization analysis is constantly analyzing and adjusting the boiler flame for a clean and efficient flame. The simplicity and autonomy of this control is its appeal. Since the control itself does so much, it requires way less training than a more complex control. I have a sales rep friend who has over 5000 of these in service and in his words “with almost no problems”. While I said ideally a control should be able to be remotely configured, I would give that up for one that was reliable enough to hardly ever need to be reprogrammed and simple enough to program that it can be explained with a video or over the phone.

Tekmar and others now have controls that that can do indoor/outdoor combined resets with thermostats that communicate the highest demand, then the control takes all of this into account. While many allow for remote login, they are still not yet part of the heat source’s brains, BUT instead they are supplanting or extending it.

Trend 2: Controls That be Configured For Multiple Functions

HBX controls exemplify another trend to watch as we march towards more intelligent controls. In order to cost-effectively have fewer SKUs, these new HBX modules can be given many functions, and have good communication functions.

Trend 3: Already Smart Heat Sources Are Getting Smarter

Air-to-Water Heat Pumps and Geo Thermal Heat Pumps are already complex machines that, in order to be efficient, usually already have a lot of “programmed intelligence” in order to run the sophisticated controls that continuously monitor and change their operation. In the heating mode in particular, adding another external control that turns them into an on-off controlled appliance reduces efficiency, although smart thermostats and smart secondary loop pumps are a good idea. Running these heat pumps in “Cooling Mode” is another story which involves integrating dehumidification.

Engineer John Williams at Chilltrix has added an intelligently integrated cooling/humidity control: by controlling humidity and the heat pump operation, it allows the unit to seek, in cooling mode, the highest water temperature that will meet the needs of cooling and dew point protection. The result is extreme high efficiency in the cooling mode, as well as very high annual efficiency as a result. Williams, who previously worked on satellite control and communication systems, said these new controls have more computing horsepower than NASA’s Apollo missions: “So as far as intelligent controls go, you guys haven’t seen anything that compares to what’s next!” ArcticAir, Raypak and others have new cold weather air to water heat pump models, meaning the geographic market for air to water heat pumps is growing. Their controls have also expanded their functionality.

Chiltrix Air To Water Heat Pump

ArcticAir, Spacepak and others have new high efficiency extreme cold weather air-to-water heat pumps. Newer, low temperature heat pumps require significant “brain power” to make these Complex machines so efficient.

If you are curious to really know how complex the control of an air to water heat pump are ask Chat GPT to give you “air to water heat pump variable speed compressor control logic model” …you will get about a ten page discussion in detail of all the many things that are considered and controlled. The top paragraph is very general but then it gives a great deal of detail.

Geothermal heat pumps used for hydronic heating can be similarly advanced. Here is a link to a video about the Water Furnace control system: (note you will initially denied access but if you click the more info box then check you are human in the 2 capcha boxes you will be able to access the video. It will open a new tab.

I conclusion I realize that is not surprising that air to water heat pumps and geo thermal heat pumps pack so much on board adaptive computing power. They are after all be far more energy efficient that traditional boilers and as such ARE the future of hydronics. Their long term future is clear since they are environmentally friendly and save energy. Unfortunately as I send this blog to press, the supply chain for these is in the short term clouded by uncertainty regarding tariffs. Since parts for these heat pumps often come from all over the world, companies may realign where they are assembled to then only pay high tariffs on the critical parts that come from high tariff countries. This may slow but will not stop the exciting evolution of these innovative and needed products.

ABOUT THE AUTHOR

Hoyt Corbett

Partner, Warm Brothers Inc.

Hoyt has been involved with hydronic heating since the early 1990’s and developed and sold a national brand of radiant floor heating that was acquired by Uponor. Subsequently, Hoyt was Associate Director of the Radiant Panel Association, the industry trade group.

He’s produced extensive technical writing on radiant floor heating, writing several major national hydronic vendor’s radiant heating design and installation manuals as well as founding and publishing The Radiant Flooring Guide.