Hydronic radiant floor heating in concrete slab: I wish I had this product when I was a young hydronic radiant contractor.

Our Company, Warm Brothers Inc. has just introduced a much faster and more convenient insulation solution for installing radiant heat in a concrete slab than was available when I was a young installer. I want to introduce this product to you; explain why you do not want to install it in the old way and point out the benefits of using InsulHeat™ instead.

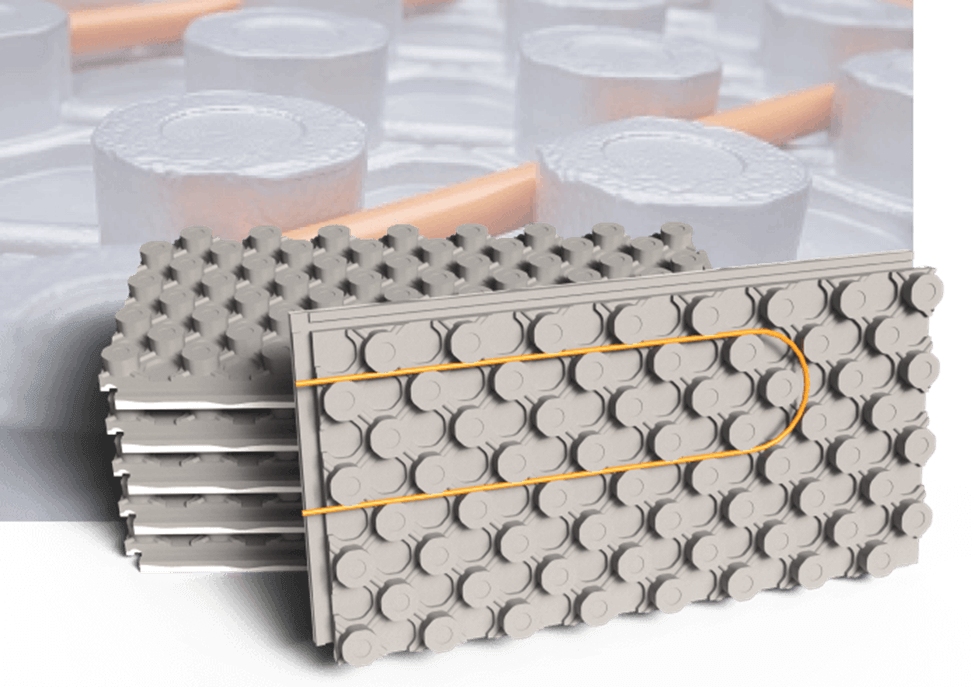

So what is InsulHeat™ Underslab™? Note that it has 4 interlocking edges that make the product easy to install and align.

InsulHeat™ Underslab™ Radiant Floor Heating Panels combine rigid insulation, a vapor barrier and a PEX tubing locking mechanism into a single solution that significantly reduces installation time. The patented “mushroom” shaped nubs lock PEX tubing in place without staples or zip ties. It is design for use under concrete slabs and provides for the placement of PEX hydronic tubing held by the nubs in the foam grid. It features

- Four-sided interlocking connectors on every panel

- Durable HIPS film acts as a vapor barrier and adds composite strength

- Inter-connected channels ensure even heat distribution

- Mushroom nubs securely lock tubing

- No need for labor intensive concrete “dobies” to support steel

- Easier installation and higher compression than blueboard

Get Factory Direct Project Quote Including Freight

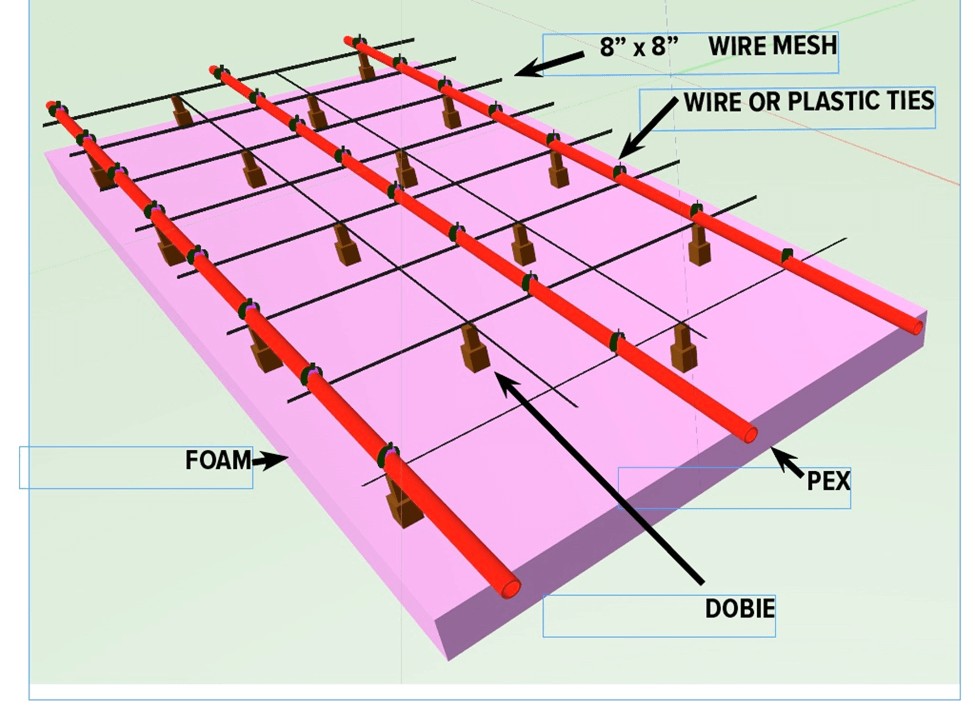

In the late 1980’s and 1990’s ….I was a hydronic contractor in the Puget Sound area of Washington State. We installed hundreds of thousands of square feet in concrete slabs in the “old way” that was common at the time. But there is now a much better “new way”. Let me explain how much more work it was to do it the “old way”:

In those days to install hydronic radiant heat in a slab, we would cut to fit and put down 2” thick 4’x 8’ pieces of EPS Foam, adding a vapor barrier. Then the next step was to put down 6” x 6” 8 guage steel mats and then wire them together.

Then we raised the mesh up on small cement blocks called “dobies” or up on wire “chairs”. This required us to then bend way over to get our hands around the steel to attach the dobies and then later the tubing ties to the steel every foot or two.

We used zip ties, the long end of which often needed to be trimmed off or use bailing wire loops with a twist tool which was a lot of work. And walking on the mesh without displacing the Dobies or chairs was often a challenge.

Later if Dobies had not been used, as the concrete pour progressed, the mesh, with the tubing, had to be pulled up into the middle of the slab. This way of installing hydronic radiant heat in a slab worked but was very slow.

When I was a contractor, the radiant jobs were spread around Puget Sound, sometimes even on islands. The joke among the crew was we were always either going around water or on the water in a ferry traveling to or from a job.

The jobs all involved a lot of travel time, and travel time was expensive. So, coming back another day could threaten profitability. Havin products that are efficient of time is and easy to estimate installation time is very important for all contractors.

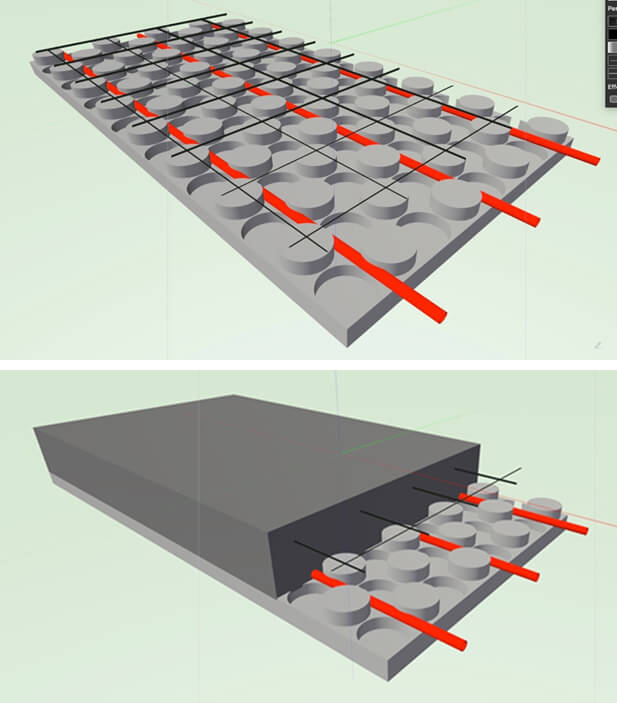

With the new product InsulHeat™ Underslab™ from Warm Brothers Inc. we are offering a newer labor-saving way to install these systems. If I had had this product when I was a contractor, I would have greatly saved installation time, travel time, money and been more profitable. Below is a graphic of the “old way” we installed hydronic radiant heating in a slab:

THE OLD WAY INVOLVED THE FOLLOWING TIME-CONSUMING DETAILS

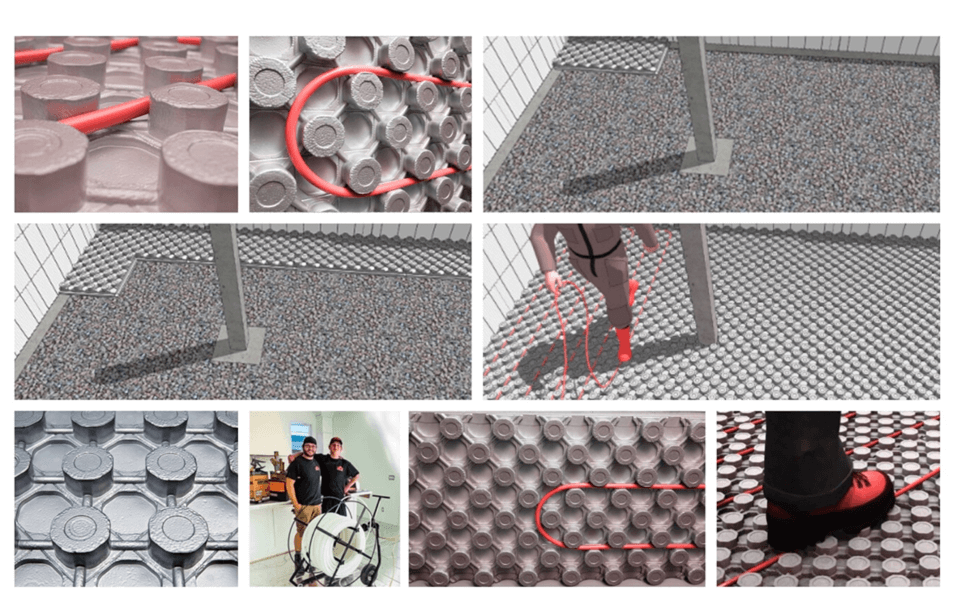

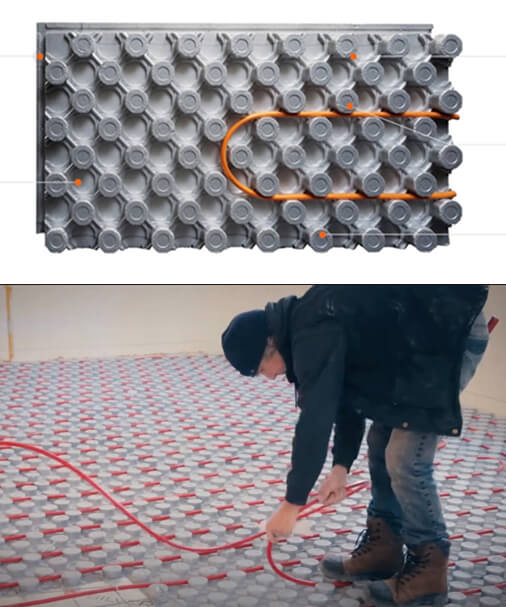

THE NEW AND BETTER WAY- INSULHEAT™ UNDERRSLAB™…JUST WALK THE TUBING IN:

This product has numerous advantages…. Speed of Install: the tubing is simply and quickly walked into the grid saving hours of back bending labor. Thus, increasing estimating certainty and improving profits. The easily handled 2’ x 4’ boards have interlocking edges that keep the boards together. There is great freedom for on-site design for experienced contractors. The tubing may be placed in multiple patterns between the nubs. The higher Nubs allow the board to be easily walked on after the tubing is is installed. Mats of 6” x 6” steel wire may be supported on the nibs and lifted as cement is poured. Since the deeper pockets are below the tubing and wire it, is possible for the installers to easily reach down with their hands and pull the mesh up to the middle of the slab as shown below.

The panels have 4 interlocking edges for stability that keep the panels in place, deep pockets to encase the PEX pipe in cement and a vapor barrier layer that also add strength.

This product is ideal for heating barns, garages, new construction slab on grade, new basements and may be used in snow melting.

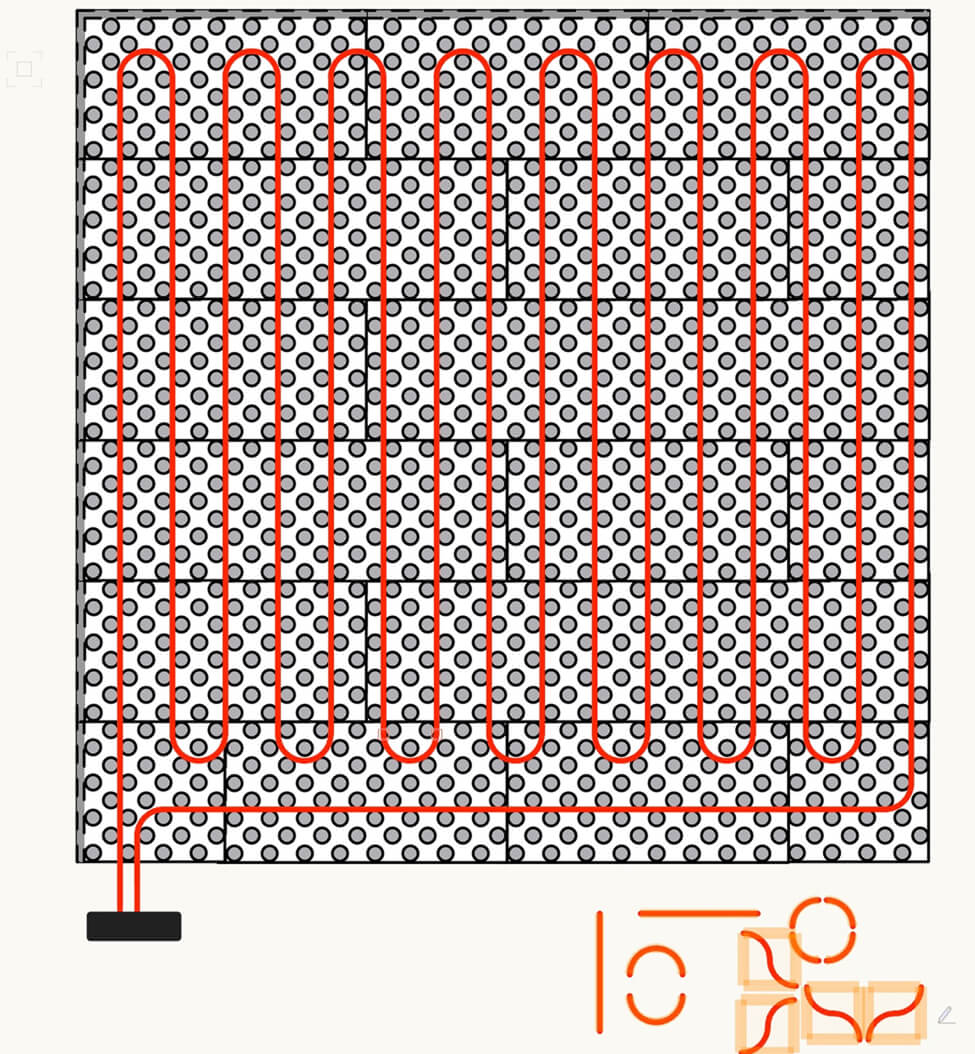

The product can be used on 6”, 9” and 12” centers. Experienced installers will discover it gives them a great deal of design freedom. Below is an example 12’ x 12’ room laid out on 9” centers. Experienced contractors can often self-design a system using this product. Less experienced users can contact us and use our design service.

Less experienced users can contact us and use our design service.

INSULHEAT DATA SHEET SHOWN BELOW IS AVAILABLE AT : https://wbiwarm.com/wp-content/uploads/2025/03/Product-data-sheet-v1.pdf

ABOUT THE AUTHOR

Hoyt Corbett

Partner, Warm Brothers Inc.

Hoyt has been involved with hydronic heating since the early 1990’s and developed and sold a national brand of radiant floor heating that was acquired by Uponor. Subsequently, Hoyt was Associate Director of the Radiant Panel Association, the industry trade group.

He’s produced extensive technical writing on radiant floor heating, writing several major national hydronic vendor’s radiant heating design and installation manuals as well as founding and publishing The Radiant Flooring Guide.

Call Hoyt at 206-369-1458, 8am to 5pm PST

or

email him at: hoyt.corbett@warmbrothersinc.com