Radiant Heat over Concrete Slab

Smart, Sustainable Heating for Modern Spaces

Installing radiant heat over concrete slab is a game-changer in today’s energy-conscious world. Whether retrofitting an older structure or designing a new one, WBI Warm’s solutions ensure high efficiency, comfort, and ease of installation.

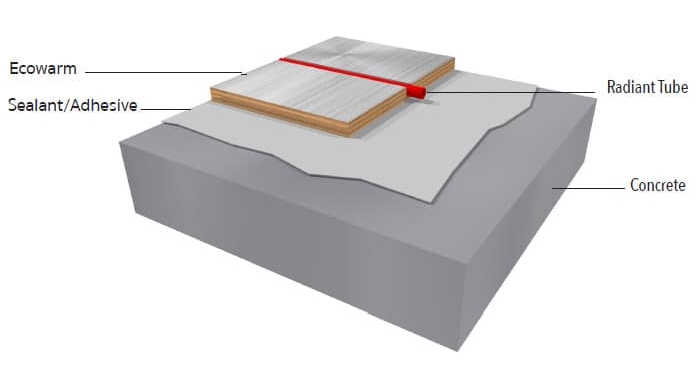

We suggest the use of integrated insulated radiant panels on top of a new or existing slab for the best R-value and excellent response for both heating up and cooling down the system. Installing radiant heat over concrete slab makes the process significantly faster while increasing comfort and efficiency. Directly attaching standard plywood or OSB to concrete introduces complications regarding moisture and cold unless insulation, at a cost, is provided separately. EPS insulation is moisture- and mold-resistant.

Why Radiant Heat Over Concrete Slab?

The old way of putting radiant tubing in a slab was popularized in the era of cheap energy. As energy prices increased, recommendations for insulation under the slab and slab edges became mandatory, increasing the cost and complications of a slab installation while not effectively increasing response.

Today’s demands for energy efficiency, fast system response, and compatibility with advanced hydronic heat pumps have made in-slab systems outdated. The new standard embraces low-mass, high-response systems, such as integrated insulated radiant panels installed over the concrete slab, which are not only more efficient but also easier to install and control.

Key Challenges of Traditional Methods:

When considering adding radiant heat to existing concrete floor systems, it’s important to understand the limitations of older installation methods. Traditional in-slab systems were once the norm, but they come with several drawbacks that impact comfort, efficiency, and cost. From slow response times to moisture concerns, these issues have led to a shift toward over-slab radiant solutions that offer better performance with fewer complications. Below are some of the important challenges associated with traditional methods:

-

Tubing embedded directly in concrete responds slowly

-

Moisture and mold issues without sufficient insulation

-

Cracking risks due to temperature fluctuations

-

Higher labor and material costs

-

Limited responsiveness to thermostat changes